Nanotechnology in Textile

Nanotechnology deals with materials having at least one dimension less than 100 nm. It includes nano-particles, nanorod, nanowires, thin films and bulk materials made of nano scale structures. Application of nanotechnology on textile materials could lead to the addition of several functional properties.

Nanotechnology, which is an emerging interdisciplinary field, is considered to provide various impacts in different science and technology areas including, but not limited to, electronics, biomedicine, materials science, and aerospace. Nanotechnology shows promise for use in higher and higher number of applications in different arenas such as textiles and clothing to impart enhanced properties and performance.

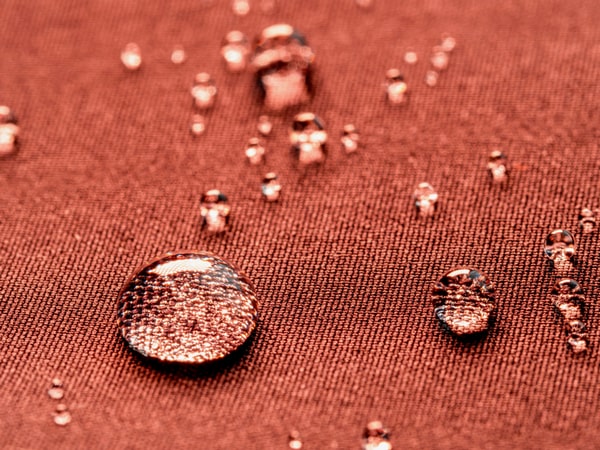

In the last two decades, we have witnessed that nanotechnology has found use in textiles for improving and/or imparting properties including smart functionalization. Nanotechnology enables certain functions including antibacterial, antistatic, self-cleaning, UV-protective, oil and water repellency, stain proof, improved moisture regain, and comfort performance in textiles while maintaining breathability, durability, and the hand. Nanotechnology applications on textiles have succeeded in attracting great interest by both research and commercial communities. The studies related to nanotechnological practices, that is, application of nanomaterials, on textiles cover in situ synthesis, cross-linking, and immobilization on textile substrates.

Nanotechnology holds great potential in the textile and clothing industry offering enhanced performance of textile manufacturing machines and processes so as to overcome the limitations of conventional methods.

With the advent of nanoscience and technology, a new area has developed in the area of textile finishing called “Nanofinishing.” Growing awareness of health and hygiene has increased the demand for bioactive or antimicrobial and UV-protecting textiles. Coating the active surfaces cause UV blocking, antimicrobial, flame retardant, water repellant and self-cleaning properties. The UV-blocking property of a fabric is enhanced when a dye, pigment, delustrant, or ultraviolet absorber finish is present that absorbs ultraviolet radiation and blocks its transmission through a fabric to the skin. Metal oxides like ZnO as UV-blocker are more stable when compared to organic UV-blocking agents. For antibacterial finishing, ZnO nanoparticles scores over nano-silver in cost-effectiveness, whiteness, and UV-blocking property.

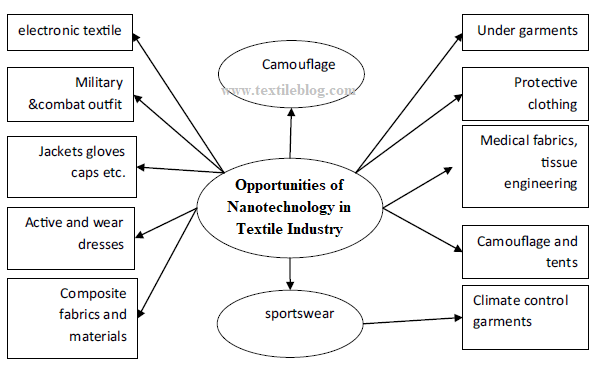

Opportunities of Nanotechnology in Textile Industry

There are many ways in which the surface properties of a fabric can be manipulated and enhanced, by implementing appropriate surface finishing, coating, and/or altering techniques, using nanotechnology. A few representative applications of fabric finishing using nanotechnology are schematically displayed in the below Figure 2.

In recent years, several attempts have been made by researchers and industries to use similar concepts of surface-engineered modifications through nanotechnology to develop high performance textile, smart and interactive textiles. The concept of surface engineering and nano-textile develops hydrophobic fabric surfaces that are capable of repelling liquids and resisting stains, while complementing the other desirable fabric attributes, such as breathability, softness, and comfort.

Nanotechnology can enrich the textile industry in several ways. First of all, and most obvious, it creates many new possibilities and improved functions in textiles. New materials can be developed, and new properties can be added to existing materials by the use of special-treated fibers, coatings and e-textiles. This will not only benefit the textile industry itself, but many other industries that make use of some form of textiles. Through this, the textile industry will be able to expand to new markets, as is currently already happening.

Nanotechnology also allows the textile industry to better anticipate to changing consumer needs. More and more, consumers are demanding functions in clothing that go beyond appearance: the quality of products has become more important. Consumers now want the product to smell pleasant, stay fresh, feel comfortable, keep clean and to be simple to care for. Also, information and communication technologies have become very important in daily life.

Nanotechnology offers manufacturers the possibility to combine these changed consumer need with (existing) textile products like sports textiles, home textiles and clothing. But nanotechnology is not just a promising new way of working with textiles, in many cases the step towards nanotechnology is part of the strategy that textile companies hope keeps them surviving in a tough textiles market. Especially in the EU textile production, nanotechnology plays an important role because of this.

Increased competition, particularly from Asia, combined with the abolition of all import quotas for textiles and clothing in the EU, US, Canada and Norway in 2008, has forced the industry to streamline and modify. It has become clear that manufacturing traditional products may no longer be enough to maintain a profitable business: the industry has to move in the direction of more innovative, high quality products in order to distinguish and compete.

Much of the focus in the EU is on technical textiles with high added value, in order to develop new markets in construction, protective clothing and medical uses for example. By finding a niche, textile companies will not have to sell lower priced goods that struggle to compete with cheaper textiles from low cost countries.

Sports / outdoor wear

1. Fibers:

Anti-microbial, odour-free, moisture managing and UV-protective properties can be added to fabrics through nanofibers.

2. Coatings:

Ultra-thin coatings with nano-sized particles can kill bacteria, keep odour out and make fabrics UV-protective and water and stain repellent.

3. E-textiles:

Devices such as GPS, solar energy technology, monitoring sensors and electronic gadgets can be integrated into garments, without affecting the flexibility of the sportsman.

You may also like: Conductive Textiles: Types, Properties and Applications

All this will enhance comfort and safety of sports and outdoor activities. With more comfort and lightness, athletes are less affected by environmental factors in the game and can focus more on improvement of their performances.

Medical textiles

1. Fibers:

Medical growth aids and ‘controlled release polymers’ can be added to fibers. Through this, certain substances or medicines can be released from the fiber at specific times or when circumstances (temperature for example) change.

You may also like: Importance of Medical Textiles in Infection Prevention and Control

2. Coatings:

Anti-bacterial and desinfective coatings can be added to all kinds of textiles used in the medical sector; clothing, bed linen, bandages, etc.

3. E-textiles:

Textile sensors can monitor and analyze body functions of patients.

All of the above will improve hygiene and ease the working conditions in hospitals, from which both patients and personnel will benefit. It will also help to prevent the spread of illnesses.

Military textiles (and other high-performance/corporate wear)

1. Fibers:

New and improved fibers can improve strength, durability, flexibility or make materials change color with their environment in order to become more invisible to the enemy. Fabrics can also be made self repairing.

2. Coatings:

Coatings can create a better protection against chemicals and fire (higher melting points), and make fabrics decontaminating, water repellent, tear repellent, self cleaning and improve strength and durability. Lightweight but super tough bullet proof vests are an example of this.

3. E-textiles:

E-textiles can improve communication through the use of for example GPS, and security through integrated identification systems.

Nanotechnology can add a lot to safety and protection of the militaries, and improve their working conditions to a large extent. It also improves situational awareness and responding to emergencies. Of course all the benefits of medical textiles can be used in the military sector as well.

You may also like: Application of Smart Textiles in Medical and Healthcare

Home textiles

1. Fibers/coatings:

All kinds of textiles (carpets, upholstery, towels, bed linen) can be made stain-free, odour-free, wear-resistant, wrinkle free, UV-protected (curtains), anti-microbial, water repellent and self cleaning through various nano-fibers and coatings.

2. E-textiles:

Electronic operation systems can be integrated in furniture, and access control systems can be used to improve safety.

Nanotechnology can ease and improve daily life by making materials easier to handle and clean and advance and ease the operation of various electronic systems. Also belonging to this category are commercial interiors, like theatres and public transport, for which these features provide an even larger benefit.

Clothing textiles

In clothing most of the above can be used to improve and enrich the functionality of daily clothing, depending on the specific demands of the consumer. The main advantage is of course that these functions can be added to the garment without affecting its physical properties like color, flexibility, weight, etc.

Thus, nanotechnology has great potential in the textile industry. It will enable growth for the technical textiles market, and provide a stronger competitive position by creating innovative, high performance products. Through this, companies in Europe and the U.S. can distinguish themselves from the cheaper producing countries, particularly in Asia.

Nanotechnology creates many possibilities in fibers, coatings and e-textiles, and is currently mostly present in non-cost sensitive fields like professional sports, military/protective textiles and medical applications, in which performance is more important than cost reduction.

Conclusion:

To sum up nanotechnology is growing by leaps and bounds and it has been introduced in many fields including the textile industries. There is a considerable potential for profitable applications of nanotechnology in cotton and other textile industries. Its application can economically extend the properties and values of textile processing and products. By deploying nanotechnology, ultra strong, durable and specific function oriented fabrics can be efficiently produced for a number of applications including medical, military and industrial apparels, etc. As mentioned, nanotechnology overcomes the limitations of applying conventional methods to impart certain properties to textile materials. There is no doubt that in the next few years, nanotechnology will penetrate into every area of textile industry.

References:

- Pollution Control in Textile Industry By S. C. Bhatia

- Nanostructured Polymer Blends and Composites in Textiles Edited By Mihai Ciocoiu and Seghir Maamir

- Smart Textiles: Wearable Nanotechnology Edited by Nazire D. Yilmaz

- Nanofibers and Nanotechnology in Textiles Edited by P. J. Brown and K. Stevens

- Pretreatment of Textile Substrates By Mathews Kolanjikombil