What is Sisal Fiber?

Sisal is a leaf fiber like PALF that comes from the sisal plant, its scientific name is Agavesisalana. It’s a cactus Agavaceae (Agave) family’s a stiff fiber traditionally used to make twine andmarine rope. It is indigenous to central America. It derives its name ‘sisal’ from the Yucatan part of Sisal on the Gulf of Mexico.

History of Sisal:

Sisal cultivation was spread to Florida, Caribbean islands and Brazil in the 19th century. Then its spread to the African countries, notably in Tanzania and Kenya, and Asia. In the late 1930’s, first commercial sisal plantings were made in Brazil. And in 1948 first sisal fiber exports from Brazil were made. Now Brazil and China are the main producing countries of Sisal.

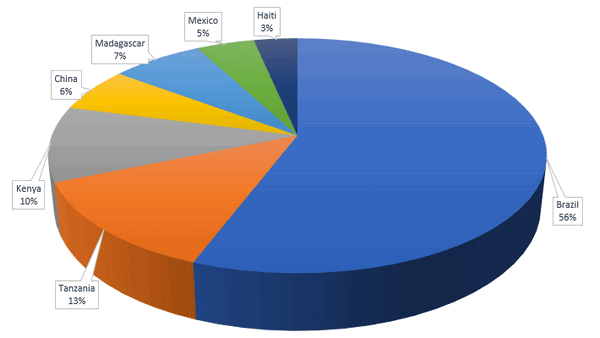

Sisal Producing Countries:

Sisal producing countries are as follow:

- Brazil,

- China,

- Tanzania,

- Kenya,

- Mexico,

- Haiti, South Africa,

- Cuba,

- Madagascar,

- Mozambique

- Indonesia,

- Thailand, others East Africa and other southern American countries.

Chemical composition of sisal fiber:

| Components | Composition (%) |

| i. Cellulose | 71.5% |

| ii. Hemi-cellulose | 18.1% |

| iii. Lignin | 5.9% |

| iv. Pectin | 2.3% |

| v. Water soluble substance | 1.7% |

| vi. Fat & Wax | 0.5% |

| vii. Ash & others | 0.7-1.5% |

Properties of Sisal Fiber:

Physical properties of sisal fibers:

- Length: 2.88 mm

- Diameter: 100-300 mm

- Width: 22.6 μm

- Tenacity: 57.2 cN/Tex

- Elongation: 3.02%

- Moisture regain: 13%

Mechanical properties of sisal:

| Characteristics | Properties |

| a. Density (g/cm3) | 1.33-1.5 |

| b. Tensile strength (MPa) | 400-700 |

| c. Young’s modulus (GPa) | 9.0-38.0 |

| d. Work of fracture (KJ/m2 ) | 98.7 |

Characteristics of Sisal:

- Exceptionally durable with low maintenance

- Does not absorb moisture easily

- Can be dyed easily and dyed color range is quite large

- Fibers have high strength, lustre and good color

- Absorbs moisture readily

- Fibers tend to be stiff and rather inflexible

- After careful processing, sisal is of creamy white color

- Strands are strong and consist of many individual fibers held together by natural gum

- Untreated sisal exhibits higher tensile modulus and hardness than the unloaded resin

- Tensile strength is maximum at the middle of yarn while moderate at the tip

- Young’s modulus increases with fiber length

- Anti-static

- Recyclable

Sisal Fiber Production:

Sisal plant grows well in a hot climate and arid regions all year round. The sisal plant can be cultivated in most soil types except clay and low tolerance to very moist saline soil conditions.

Relatively simple cultivation as it is resilient to disease and easy-care requirement is low compared to other crops. Sisal could be harvested from one-two years after planting. Its productive life can reach up to 12 years and produces 180-240 leaves (depends on location). So, cultivation of sisal fiber can be a solution of poverty problem in poor countries.

Production and processing:

- Adult plants send up a lot of leaves almost from ground level. The leaves almost from ground level. Leaves are firm, fleshy, and form a rosette on a short trunk.

- After 6-7 years of growth, the sisal plant seeds out a flower stalk that rises to 20 feet long. When it has flowered, the plant produces tiny buds, which develop into small plants; these fall to the ground and take root, then the parent plant dies.

- Leaves are harvested when the plants are 2.5 to 4 years old and at intervals until the plant eventually dies. A good plant may yield 400 leaves during its life time and leaf may contain 1000 fibers.

- The outer mature leaves are cut away and treated in machine which scrap the pulpy material from the fibers. After washing, the fibers are dried and bleached in sun or oven dried.

- Sisal has good affinity for direct, reactive and acid dye stuffs, which provide attractive shades of good light fastness.

End Uses of Sisal:

- One of the most valuable of all cordage fibers.

- It is too stiff and can be used in power transmission, in which it has to run through pulleys or over wheels.

- Now-a-days, widely used in marine ropes and hawsers particularly in under developed areas.

- Baler, binder twine, sacks, paper filter and other industrial uses.

- Ladies hats, mats and rugs are made due to strength, lustre and good color.

Application of Sisal Fiber:

Gradation of sisal fiber: Sisal is broadly categorized under three grades.

Which are applied in various industries are as follow:

1. Low-grade: cellulose and hemicellulose portion are mainly used in:

- Paper industry

- Cordage industry

2. Medium-grade: used in making of binder twine, ropes, bales

- Agriculture

- Marine

- General industrial purpose

3. High-grade: used by blending itself with wool and acrylic for softer hand

- Carpet industry

Table: Application of sisal fiber

| Industrial Area | Applications |

| a) Agricultural | Juice, fragments of leaves, and particles of crushed parenchymatous tissue, are used as fertilizer and animal feed. Also used as binders’ twine, bale binding twine, and different agro-textile materials. |

| b) Cordage industry | Ropes, baler and binder’s twine. |

| c) Paper industry | Lower quality’s sisal fiber are used to make paper in paper industry. |

| d) Automobile Industry | Used in car doors, panels, package holders, ceilings, wheel wells, consoles, skid plates and the like to reduce fuel consumption |

| e) Construction Industry | Short sisal fiber used to make High-quality sofa, Wadding mat and others Pulp Constructing materials. |

| f) Floor covering | Higher quality’s sisal fiber are used to make carpet, mattresses, rugs, and wall covering. |

| g) Geotextiles | As a sandwiching natural component between layers of polyester. Used as packaging, tying and gardening materials. |

| h) Buildtech | Used to reduce the equipment of abrasion and subsequent reduction of retooling costs. |

| i) Other uses: | Dart board, buffing cloth, handicrafts, Filter manufacturing, Geotextiles, Agro-textile, Buildtex, Automobile industry, and so on. |

Future Scope and Conclusion:

Sisal fibers could be used to be a good example of hybrid composites. Cause, it has reinforcement by two or more fibers in a single matrix leads to a great diversity of material properties. In near future, ceramic fibers and sisal could be combined to produce hybrid composites. That will take full advantage of the best properties of constituents. But the extraction of sisal fiber uses a few percentages of the plant. Some attempts have to take to improve economic viability which are focused on utilizing the waste material.

References:

- Mechanical and physical properties of sisal and hybrid sisal fiber-reinforced polymer composites By J. Naveen, M. Jawaid, P. Amuthakkannan, M. Chandrasekar

- Natural Dyes and Pigments: Extraction and Applications by Rym Mansour

- http://www.worldjute.com/about_jute/sisal.html

- https://www.textilesphere.com/2020/03/sisal-fiber-properties-applications.html

- https://www.textileadvisor.com/2020/03/sisal-fibre-cultivation-and-uses.html

- https://www.fibre2fashion.com/industry-article/2394/sisal-fibre-an-overview

Author of this Article:

Md. Mahedi Hasan

B.Sc. in Textile Engineering

Textile Engineering College, Noakhali.

Email: mh18.bd@gmail.com