What is Spandex Fiber?

Spandex is an elastic type fiber which has an extension at a break in excess of 200% with rapid recovery when the tension gets released. Spandex fibers made by DuPont of USA bears the trade name ‘Lycra’. Spandex is also called elastomeric fiber because it is produced from an elastic type polymer, called polyurethane which has stretchability like natural rubber. Spandex fiber can be defined as “a manufactured fiber in which the fiber forming substance is a long-chain synthetic polymer compromised of at least 85% of segmented polyurethane”.

Spandex, Lycra or elastane is a synthetic fiber known for its exceptional elasticity. It is made up of a long chain polymer called polyurethane, which is produced by reacting a polyester with a diisocyanate. Spandex gained interest quickly due to it’s superiority to the strength in durability of rubber. Spandex also has a better resistance to dry heat and oil, in comparison to rubber. The level of comfort and wicking ability found in Spandex are unparalleled, and do not exist in such high amount with any other fabric.

Spandex or elastomeric segmented polyurethane is a thermoplastic elastomer which has good tensile strength than any other rubber. They exhibit excellent resistances to tearing and abrasion, action of body oils and lotions, heat and perspiration and to the action of oxygen or ozone. However, they show relatively poor resistance to acids, alkalis and to steaming (causing hydrolytic degradation) than the conventional rubbers.

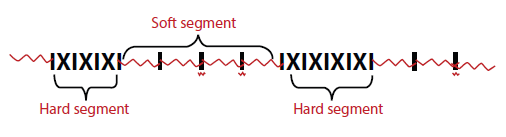

The polymer of elastomeric fiber consists of two segments, named soft and hard segments (Figure 2). The soft segments oriented in random style with minimum crystallinity and the molecular chains of these segments are coiled by folding on themselves. The stretchability and flexibility of spandex fiber are due to for these soft segments. On the other hand, the hard segments are clung to each other by strong hydrogen bonding.

When stretched, the coiled soft segments get opening out more than 200% to their original length and the hard segments prevent the fiber breakage. The flexible extended soft segments slip back into their original configuration when the load is removed.

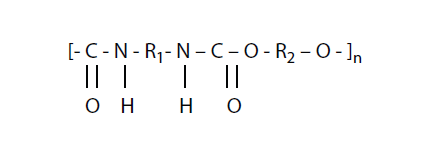

Chemically spandex is a polymer of urethane (–NH–COO–). This is 100% synthetic fiber (Figure 3). Some of the polyurethane fibers are now on the market. In Britain, Courtaulds has marked “Spanzelle”. “Vyrene” is made by Dunlop Rubber Co. and Du Pont has made “Lycra”.

Spandex is being used in a continually widening array of clothing articles, including woven and knits, and synthetics and natural fibers.

Properties / Characteristics of Spandex Fiber:

Physical properties of spandex fiber:

It has a density of 1–1.05 g/cc which is close to the water density. Melting temperature of spandex is in the range of 175–178°C. Its excellent elongation value can be as high as 700%. The elongation at break generally falls in between 350% and 700% with an elastic recovery of 99% at 200% extension. However, the elastic modulus is very low and lies in the range of 0.007–0.020 g/day.

Others physical properties of spandex fiber are given below:

- Cross section: Spandex filaments are extruded usually from circular orifices, but the evaporation of solvent or the effects of drying may produce non-circular cross-sectional shapes. This may take various forms. In the multi-filament yarns, individual filaments are often fused together in places. The number of filaments in a yarn may be as few as 12 or as many as 50;the linear density of filaments ranges from 0.1 to 3 tex (g/km).

- Length: It can be of any length. May be used as filament or staple fiber

- Colour: It has white or nearly white colour.

- Luster: It has usually dull luster.

- Strength: Low strength compared to most other synthetic fiber.

- Specific gravity: Specific gravity of Spandex fibers is about 1.20-1.25.

- Elasticity: Elastic properties are excellent. This is the outstanding characteristic of the fiber.

- Heat: The heat resistance varies considerably amongst the different degrades over 300 F.

- Flammability: It Burn slowly.

- Electrical conductivity: It has Low electrical conductivity.

- Breaking tenacity: 0.6 to 0.9grams/denier.

Chemical properties of spandex fiber:

The fibers are well resistant to alkalis but prone to yellowing in acid solution. The fibers are also resistant to peroxide bleaching, ozone, chlorine, and UV radiation. Disperse dye, acid dye and basic dye can be used for the coloration of spandex fiber. The water absorption capacity of this fiber is low (moisture regain=1.3%).

Others chemical properties of spandex fiber are given below:

- Acid: Good resistance to most of acids unless exposure is over 24 hours.

- Alkalies: Good resistance to most of the alkalies, but some types of alkalies may damage the fiber.

- Organic solvents: Offer resistance to dry cleaning solvents.

- Bleaches: Can be degreaded by sodium hypochloride. chlorine bleach should not be used.

- Dyeing: A full range of coloures is available. Some types are more difficult to dye than others.

The Spinning of Spandex Fiber:

Spandex fiber can be spun by melt spinning, dry spinning or wet spinning. For dry and wet spinning dimethylformamide is used as a solvent. Melt spun technique is also suitable as its melting temperature is in the range of 175–178°C.

Uses of Spandex Fiber:

They find applications as oil seals, footwear soles and heels, construction of conveyor belts, printing rollers, fabric coatings, water-proof items, tank-lining in some chemical plants, cable sheathing, pump impellers, gaskets and diaphragms, industrial hoses etc. Heat setting treatment is used for ensuring dimensional stability of fabrics and garments. Spandex fiber can also be used as accessories in belts, gloves, socks, tights; in sports textiles like swimwear, cycling jersey, apparel for exercise; in apparel like leggings, shorts, skinny jeans, ski pants, yoga pants, brassieres, hosiery, surgical hose, etc.

You may also like:

- Chemical Fiber Spinning Methods for Filament Yarns

- Properties, Manufacturing and Application of Fiberglass

- Ceramic Fiber: Properties, Production and Applications