What is Fancy Yarn?

The term ‘fancy yarns’ may be taken to cover all fancy and novelty effects, while ‘fancy doubled yarns’ covers yarn and fiber effects. Color effects and effects based on metallic components are also available. While some are important for the embellishment of plain fabrics, many are used with great success as components in ‘fancy fabrics’ or as design elements within an otherwise simple fabric structure.

Yarn refers to a structure composed of continuous length of interlocked fibers. They are suitable for use in the production of textiles, sewing, crocheting, knitting, weaving, embroidery and rope making. However, fancy yarn deviates from the normal yarns. These deviations occur mainly due to introduction of deliberate decorative discontinuities in the form of color, structure or both. The size and value of the market for fancy yarn is negligible. However, fancy yarns appear mainly in high value items, so their small volumes cannot be ignored. The fancy yarn gives a fancy touch to the fabrics to a broad range of end uses. Significant demand for the fancy yams is the ladies and children outerwear.

The basic profiles of the fancy yarns are Spiral, Gimp, Slub, Knob, Loop, Cover, Chenille and Snarl yarns. The fancy effect can be optioned with two ways:

- By twisting and or doubling technique

- With spun effect by means of fibers. The effects may be randomized and regular effects.

Properties of Fancy Yarns:

There is still much potential for research to discover the physical properties of the different types of yarn, depending on the machinery used to make them or the particular structures involved. In particular, the properties that might be of interest specifically to commercial users of fancy yarns include strength, wear resistance, flexibility, comfort, stretch properties, and suitability for a particular manufacturing or dyeing process. Other potentially useful and interesting research might cover, for example, the effect of the production rate upon the behavior of the yarn in further processing, the potential for the inclusion of lycra to improve stretch properties or the details of changes in handle resulting from different means of production for each structure. Since superficially similar yarns may now be produced by several different processes, it behaves the user to select a yarn produced in the fashion that best suits the processing it will subsequently receive.

Basic Principle of Fancy Yarn:

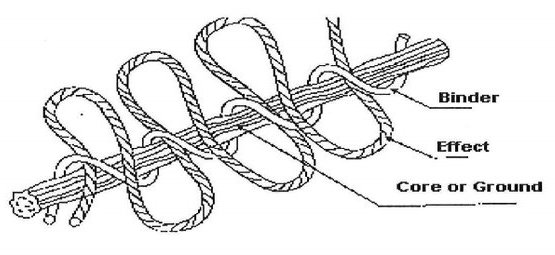

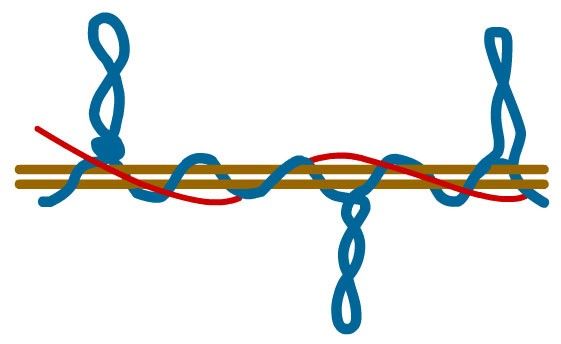

The basic structure of a fancy doubled yarn consists of ‘core’ threads, an ‘effect material’, and a ‘binder’ which, as the name suggests, ensures that the entire structure holds together. A ground (core) component, an effect component and a binder in a fancy yarn are shown in the following figure. To obtain structural effect, longer length of effect component, relative to ground component must be present to form the required effect. Twisting of the effect component on to the ground component will produce aesthetic effect.

The basic principle is therefore to feed the ground and effect component at different speeds in to the twisting element. The percentage ratio of the effect component to the ground component is called over feed ratio.

In developing an understanding of yarn structures and types, there is no substitute for handling yarns and analyzing their structure and form. It is a valuable exercise to create a private collection of interesting yarns, and their use in fabrics.

The more easily discovered features might include, for example:

- Count

- Fibre or fibres used

- Basic structure (is the yarn a slub, bouclé, chenille, chainette, or a yarn involving several fancy effect yarns . . .?)

- Number of component threads

- Purpose of each component thread (is it a core, effect, binder . . .?)

- Intended use for the yarn itself (knit, weave, embellishment . . .?).

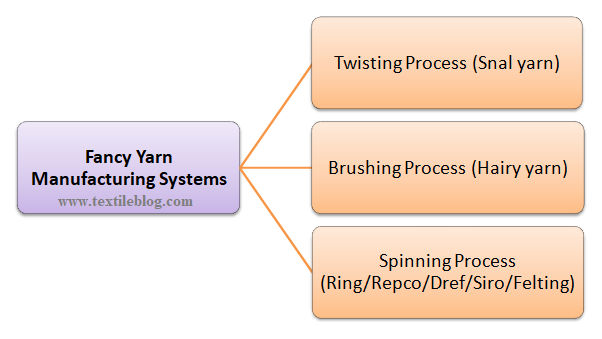

Fancy Yarn Manufacturing Systems:

The above figure shows the fancy yarn manufacturing system. The classification is made based on the twisting, brushing and spinning process.

Different Types of Fancy Yarns:

Spiral Yarn:

Plying technique used here. Typically, two single yarns of different thickness and twist level are plied together with slight over feed of course yarn.

The spiral fancy yarn is a plied yarn with smooth spiraling of one component around the others. Delivering one or more of its components at a greater speed can produce fancy yarn with spirals, so the shorter length of the component forms the core, while the greater length of the components creates the spirals.

It shown in the following figure:

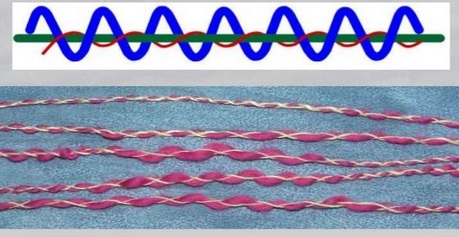

Gimp Yarn:

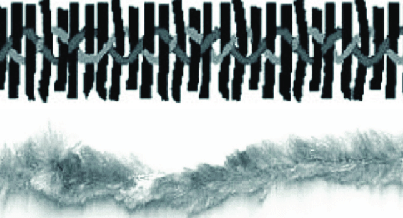

Both the plying technique and the hollow spindle process could be used to make this yarn. Using hollow spindle process two ground yarns on which the drafted ribbon can be made to buckle in to the form of wavy shape, a typical shown in the figure:

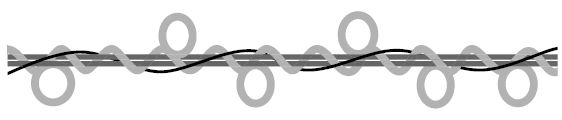

Loop Yarn:

The threading arrangement of the component yarns to form loops is similar to that of gimp shown in the following figure. The considerations to for the loop yarns are the type of fibers, level of twist applied and the percentage of over feed employed at the profile stage.

Snarl Yarns:

This also produced by plying process. The profile component is a highly twisted yarn shown in the figure:

Knob Yarns:

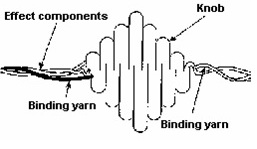

The knob yarns can be constructed by the joining or the plying system by using the over feed of 150-200%, but the profile is visually not as well as defined in the spinning process because a drafted ribbon is used as the profile component.

Knop yarn contains prominent bunches of its component arranged at regular or irregular intervals. Using rollers capable of being operated independently usually makes this fancy yarn: core component-intermittent delivery and effect component – continuous delivery. So the effect component joins the core and is gathered into bunch or knop by the insertion of twist.

The Knob yarn shown in the figure:

Nepp Yarns:

These are made on the woollen system. They show strongly contrasting spots on the surface of the yarn, which are made by dropping in small balls of wool at the latter part of the carding process. The nepps may also be incorporated in the blend, with the carding machine set to ensure that these small lumps are not carded out.

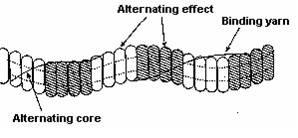

Cover Yarn:

The cover yarns are made by plying process the threading arrangement is identical to the knob yarn. Two pair of rollers controlling the yarns are made to start stop as required. However instead of stopping, each pair of rollers will in turn slow to a speed that allows the other yarn to wrap around that fed by slowed rollers. The level of twist required is high in order of 1600t/m. A typical structure of the Cover yarn shown in the Figure:

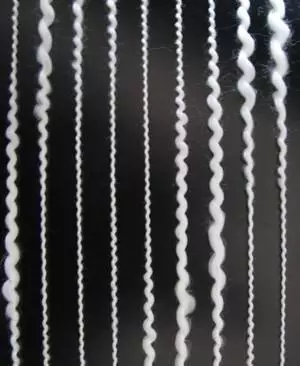

Slub Yarns:

The production of the ground and injected Slub yarns was considered this case the roving is replaced as a profile component, roving periodically stop and start accordingly to the required Slub length and spacing. The Slub thickness is determined by the roving count.

Chenille Yarn:

This was made originally by the Leno weaving two weft yarns are placed between each crossing of the weft yarns. After weaving the weft, length extended between the warp yarns is cut to produce the pile effect. This traditional Chenille yarn shown in the figure:

There are also many types of fancy yarns, such as:

- Stripe yarn

- Boucle yarn

- Marl yarn

- Cloud or grandrelle yarn

- Eccentric yarn

- Flake yarns

- Eyelash or feather yarn

- Pompom yarn

- Button yarn

- Diamond yarn

- Tape yarn

- Fasciated yarn

- Metallic Yarns

Applications for Fancy Yarns:

Homewares:

Upholstery and home furnishings have offered a relatively new field to spinners of fancy yarns over the past 20 years. The now surprisingly long-lived trend for ‘shabby chic’ furnishing fabrics favors the use of fabrics involving fancy yarns, because the inherently uneven surface of a fancy yarn is enhanced when it is woven or knitted into a fabric, giving that fabric itself a broken surface. In addition to drapes and upholstery – which are expected to have a certain durability – fancy yarns have been used lavishly in accessories such as cushions and throws. Furthermore, as textural details have become an important part of interior design, an additional application for all fancy yarns has been found in making tassels and braids for furnishings and drapes.

Fashion:

Fancy yarns have wide-ranging application in apparel at all levels of the market. Where once the extreme complexity and difficulty of making and using fancy yarns inhibited their production in sufficient quantity or at a low enough price for the mass market, improved process control has now greatly extended their market penetration. In particular, fancy yarns have become an increasingly prominent part of the revived hand knitting market, although this can best be seen as further evidence for the overall change in attitude within the market, which is discussed in the next section.

Market Potential of Fancy Yarns:

While considering the market for fancy yarns, we need to remember that these goods are not commodity items, and nor will they ever be. Their purpose is to add color or texture, or both. So market value of fancy yarns will remain negligible with compared to the rest of the textile market. But due to the consequence of liberalization in trade with countries like China a great interest in fancy yarn area is noticed in textile market all over the world. Due to liberalization in fancy yarns sector trade between Europe and Asia, the main Asian producers of fancy yarns compete with each other to offer more and more sophisticated products.

Future Trends in Fancy Yarns:

Whereas once it was lamented that fancy yarns only ever experience very short periods of popularity because of their expense and the difficulty of meeting demand, over the past ten years fancy yarns of one sort or another have remained available in the high street more or less continually. We can expect that this trend will continue. Although lot sizes are smaller than they were, there is the opportunity for great variety in the effects chosen and employed each season. In some market sectors, new effects may be introduced six times or even more often every year.

The most marked changes have lain in a new understanding of, and attitude towards, the final customer. The development of hand-knitting yarns that can create dramatic, interesting and fashionable effects without demanding great skill from the knitter is one example of this.

In the future, we can expect further consolidation, and perhaps still greater agility in the markets. It seems reasonable to assume that the last word on yarn structures has not yet been spoken.

Conclusion:

Fancy yarns are special products of spinning with deliberately introduced irregular characteristics in either diameter, bulk or in color. Products made from fancy yarns are not commodity items. Although market value of fancy yarns is negligible with compared to the rest of the textile market research and development in this area has become very important. This is mainly attributed to the value addition obtained in terms of fashion or function of the yarn. The production of fancy yarns has been differentiated and enriched in such a scale that makes almost impossible to categorize and standardize all the products. Regardless the explosion of the new fancy yarns products without the proper standardization procedure or at least classification, the process of evolution of yarns, in general, lasts, both in the context of the components and final products as well as trade.

Production of Fancy yarns is a combination of art and science. There is lot of scope for the innovators to develop new products in Textiles using Fancy yarns. Apart from the Domestic market, Export of fancy yarns, Fabrics and Garments may provide great Opportunities in future.

References:

- Rameshkumar, C., Prakash, S.P., Kumar, S.J.K. and Anbumani, N. (2008). Wrap spinning for fancy and high performance yarns. The Indian Textile Journal, December, 15-26.

- Pouresfandiari, F. (2003). New method of producing loop fancy yarns on a modified open end rotor spinning frame. Textile Research J., 73, 209-215.

- Testore and Minero, Study on fundamental parameters of some Fancy yarns, Journal of Textile Institute-1988.

- Textile and Clothing Design Technology Edited by Tom Cassidy and Parikshit Goswami

- Specialist Yarn and Fabric Structures: Developments and Applications Edited by R. H. Gong

- Fancy Yarns: Their Manufacture and Application By R H Gong and R M Wright

- Technical Textile Yarns: Industrial and Medical Applications Edited by R. Alagirusamy and A. Das

- https://textilelearner.net/different-types-of-fancy-yarns/