Effect of Pretreatment Process on Dyeing of Viscose Fabric with Reactive Dyestuff

Mohammod Habibur Rahman & Ataur Rahman

Department of Textile Engineering

Dhaka University of Engineering & Technology (DUET)

Gazipur-1700, Bangladesh

The pretreatment process significantly affects the dyeing performance of viscose fabric with reactive dyes. Proper pretreatment enhances dye uptake, color fastness, and overall fabric quality.

Objects:

- To increase quality of dyed fabric.

- Cost minimization

- Best process selection

- Observation of different pretreatment process

- Compare various pretreatment process

Operational activities:

1. Scouring & bleaching:

- Different amount of wetting agent use.

- Different amount of detergent use.

- Different types of detergent use.

- Different amount of caustic soda (NaOH) and soda ash (Na2CO3) apply.

- Different amount of Hydrogen peroxide (H2O2) use.

- Various liquor ratio use.

Note: When one parameter change then others parameter will remain constant.

2. Dyeing:

Our main object is to observation of different pretreatment process effect for same dyeing recipe. Which process gives us better result.

3. Finishing:

Methodology:

The methodology is as follows-

Planning & budgeting

↓

Collection of viscose fabric

↓

Collection of chemicals & dyes

↓

Various pretreatment & dyeing procedure

↓

Observation of results

↓

Compare of results

↓

Select best alternative

Chemicals and Dyes:

- 1.Wetting agent

- Detergent

- Sequestering agent

- Caustic soda (NaOH)

- Soda ash (Na2CO3)

- Stabilizer

- Anti creasing agent

- Antifoaming agent

- Salt

- Hydrogen per oxide (H2O2)

- Acetic acid

- Leveling agent

- Softener

- Enzyme

- Peroxide killer

- Lubricant

- Dyes

- Bicromate or fitcary

- Copper sulphate

Modal fabric dyeing (Deep Shade):

Fabric construction: 40/s Modal cotton S/J & 20D Lycra, GSM =150, 3424, SL = 2.9 mm Dia = 75″ (open)

| Chemicals/ mlt | Recipe | Process | Dozing /inject | Running & pH |

| Materials | Batch | Heat setting | 190°c to 200°c through stentering | |

| Material | Batch | Loading | Take water before start m/c at 1:10 | |

| Detergent (NOPS) | 1 g/l | Cold wash | Normal temp. | 40˚C – 10´ |

| Stabilizer & sequestering (CONL) | 0.5 g/l | |||

| Anti creasing (NC) | 0.5 g/l | |||

| Anti forming | 0.5 g / l | |||

| Viscose color | 3 g/l | Scouring & bleaching | Dozing 40˚C – 7´ | 70˚C – 60´ |

| BD | Before BD absorbency check | |||

| Per oxide killer (Biokil) | 0.3 g/l | Inject | 40˚C – 10´ | |

| Hot | – | Washing | – | 80˚C -10´ |

| Acetic acid | 0.5 g/l | Neutralization | Inject | 50˚C – 10´ for pH = 6.00 ~ 7.00 |

| Wash | – | |||

| Leveling ( REB) | 1 g/l | Leveling | Temperature Increase at 60˚c | 60°C – 10 ´ |

| Sequestering (CONL) | 0.5 g/l | |||

| Anti creasing ( NC ) | 0.5 g/l | |||

| Salt | 80 g/l | Migration | 5 % dozing 60˚c – 10´95% doz. 10´ | 60˚C – 10´ 60˚C – 10´ pH below 7 |

| Salt | ||||

| R/T orange ME – 2RL | 3.46% | Color | Dozing 60˚C – 20´ | 60˚C – 10´ |

| EVR. Red 3BS | 2.76 % | |||

| Cotton blue | 0.0044% | |||

| Soda ash | 20 g/l | Fixation | 1% dozing 60˚C – 20´5% – 20´94% – 20´ | 60˚C – 10´ 60˚C – 10´ pH 10.5 60˚C – 10´ |

| Soda ash | ||||

| Soda ash | ||||

| BD | Before BD sample check (Shade) | |||

| Acetic acid | 0.5 g/l | Neutralization | Inject | 40˚C – 10´ |

| BD | Before BD/rinse sample check (Shade) | |||

| RSK | 1 g/l | Soaping | Inject | 80˚C – 10´ |

| BD | Before BD /rinse sample check (Shade & soft) | |||

| Fixer | 1 g/l | Fixing | Inject | 40˚C -10´ |

| Materials | Unloading | |||

Table: Modal fabric dyeing process with Reactive dye

N.B: Viscose fabric dyeing process is same as to Model fabric dyeing process. Do not use caustic & peroxide, viscose color is a multifunctional chemical which perform scouring & bleaching. Viscose fiber has more absorbency than cotton so liquor ratio uses 1:10. So possibility to uneven dye to prevent it used high liquor ratio & carefully dozing salt and soda.

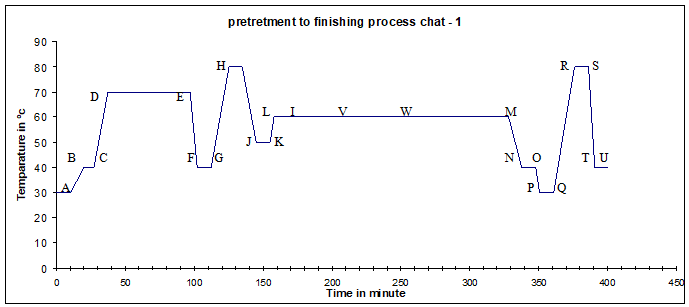

Where,

A= Cold water loading

B= Fabric, Detergent, Stabilizer, sequestering, Anti creasing, Anti forming Inject.

C= Viscose color (Scouring & Bleaching Agent) dozing then temperature increase at 3ºc/min.

D= Scouring and bleaching running

E = Scouring and bleaching bath drain

F= Peroxide killer Inject

G= Temperature Increase 3ºc/min

H= Hot wash

J= Neutralization to remove residual alkali

K= Fresh water taken for dyeing then temperature Increase

L= Leveling, Sequestering, Anti creasing, dozing.

I= Salt dozing,

V= Color dozing

W= Soda ash dozing

M= Color bath drain

N= Fresh water taken and Neutralization

O= Acid Bath drain

P= Fresh water taken for soaping

Q= Soaping agent Inject then temperature increase 3ºc/min

R= RSK (soaping) running

S= Soap bath drain

T= Fixer Inject

U= Fabric Unloading

You may also like: General Dyeing Procedure of Cotton Fabric with Recipe