Color Fastness to Rubbing / Crocking:

Rubbing fastness means a change in color of the rubbed textile (by bleeding and fading). Crocking fastness is the migration of color from the dyed surface to another surface by intense contact, for example by rubbing (soiling/staining).

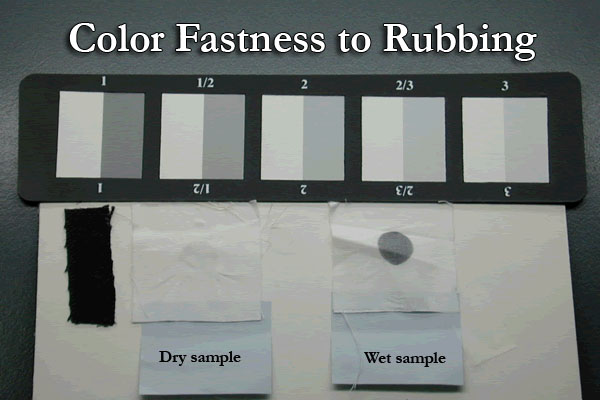

Crocking is the transfer of the colorants from the surface of the colored fabric or yarn to adjacent area of the same fabric or the other fabric principally by rubbing. Under controlled conditions colored specimen is rubbed with the white test cloth. Color transfer to the white cloth is evaluated by comparison with the standard Gray Scale.

Determination of Color Fastness to Rubbing

Purpose and Scope:

This test method is designed to determine the amount of color transferred from the surface of colored textile materials to other surfaces by rubbing. It is applicable to textiles made from all fibers in the form of yarn or fabric whether dyed, printed or otherwise colored. It is not recommended for use for carpets or for prints where the singling out of areas may be too small using this method.

Test procedures employing white test cloth squares, both dry and wet with water, are given.

As washing, dry cleaning, shrinkage, ironing, finishing, etc., may affect the degree of color transfer from a material, the test may be made before, after, or before and after any such treatment.

Principle:

A colored test specimen is rubbed with white crock test cloth under controlled conditions. Color transferred to the white test cloth is assessed by a comparison with the Gray Scale for Staining or the Chromatic Transference Scale and a grade is assigned.

Apparatus and Materials:

- Crockmeter or comparable alternate apparatus.

- Test Cloth, cut in 50 mm squares.

- Chromatic Transference Scale.

- Gray Scale for Staining.

- White Textile Blotting Paper.

- Specimen Holder for Crockmeter.

- In-house poor crocking cloth.

- Crockmeter Verification Cloth.

Sample Preparation:

Prepare two pieces of fabric measuring 5 × 13 cm, one for dry rubbing and the other for wet rubbing. The fabric is cut along the warp so that the longer side is parallel to the direction of warp. In case where the test sample contains more than one color, multiple samples covering all the colors are prepared and crocking test is performed on each color.

Color Fastness to Rubbing Test Procedure:

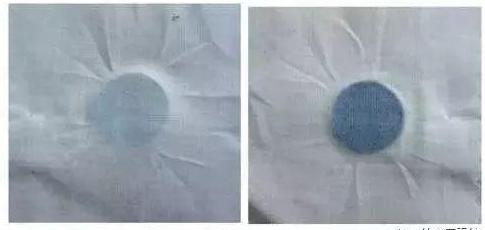

The test specimen is placed on the base of the Crockmeter and a square of white test cloth is rubbed on the colored specimen by means of the Crockmeter finger (dry test cloth for dry crocking; test cloth wet out in distilled water for wet test; wet pickup 65+/- 5%). The sample is rubbed twenty times; after this the staining of the white cloth is determined.

Complete process are point out below:

Prepare the test specimen and fasten it to the base board of the testing device by means of clamps. Care should be taken to ensure that there are no folds or creases on the surface.

When testing multicolored textiles care should be taken to position the specimen in such a way that all colors of the design are rubbed in the test. Alternatively, if the areas of color are sufficiently large, more test specimens may be taken to assess individual colors separately.

- Initially the crock meter is set at 10 strokes, the stroke length is kept as 100 mm and the downward force of the fingers is set as 9 N for normal fabric and the diameter of the finger is 16 mm.

- Dry rubbing: Mount the dry cotton rubbing cloth (5 cm × 5 cm) on the finger and fasten with a clamp. Start the crock meter and when the test is complete the fabric sample and the rubbing cloth are taken and kept aside for assessment.

- Wet rubbing: Wet the cotton rubbing cloth in distilled water, squeeze out excess water by using blotting paper so that it absorbs about 65+5% of water. Now mount this wet rubbing cloth on the finger and repeat the testing. After completing the test, dry the wet rubbing cloth in room temperature and then assess the rubbing cloth.

- Use the grey scale for assessing staining on the rubbing cloth and assign grades accordingly.

How to Improve Rubbing Fastness?

Rubbing fastness is improved by formation of films coating the fibers, reduced rubbing of the smoothed surface and by hydrophobation. The finish products can behave similarly to lubricants in reducing the rubbing forces. Generally also finishes that reduce the swelling of hydrophilic fibers cause an effect (durable press and easy-care finishes with crosslinking agents for cellulose fibers). Less migration of dyestuff but poorer tensile strength of the cellulose fiber cause more abrasion.

Improved rubbing fastness can be achieved with partially hydrolysed polyvinylacetate (PVAc/PVA) or polyvinylether and the application of pigment binders, mostly based on acrylic copolymers similar to those used as hand builders. Application methods mostly use pad–dry techniques.

You may also like: How to Improve the Fastness Properties of Pigment Printed Cotton Fabric