What is 3D body scanning technology?

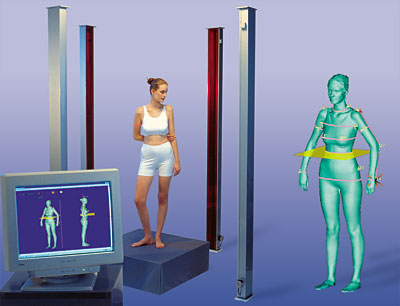

3D body scanning technology is a non-contact, measurement system that uses infrared or leaser depth sensing and imaging technology to produce a digital soft copy of the surface geometry of the human body.

Body scanning on garment development:

3D body scanning technology is a tool which has been a commercially viable product with implications on garments design and development since the start of the 21th century. The development of 3D body scanning technology is grown by the 3D software from companies like Gerber, Lectra, Optitex, V-Stitcher, etc allowing for virtual modelling and enhancing the possibilities of body scanning in apparel development.

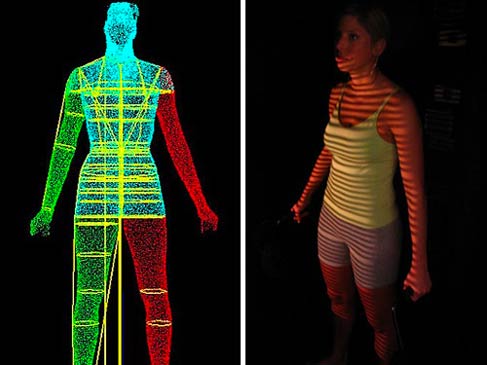

3D Body scanning technology makes use of laser, light and others radar technologies. Generally, the scanners works by projecting structured light on the body surface. Then it records through image capture technology. These data are then used to create more than 1 million point clouds X, Y and Z coordinates which describe the body as a 3D object. The data helps to be processed to create an avatar from which measurements can be extracted. Now, the avatar enables to the custom analysis of an individual in a fixed posture and the extraction of custom measurements. That can be used to classify the size and shape or to support apparel development.

3D Body scanning technology is a rapid and precise way of generating 3D images of human body. The scanner can scan the whole human body in less than 15 seconds and rapidly produces a true-to-scale 3D body model for apparel.

Body scanning technology for apparel used as following:

- Custom fitting apparel

- Designing and producing apparel

- Body shape analysis

- Sizing surveys: Size USA

- Apparel sizing standards development

- 3-D product development, including apparel, automotive seating, and other equipment applications

- Producing virtual manikins and models for online Shopping

Discussion of findings on 3D body scanner:

Operational parameters of the 3D body scanner have auto-registration features and uses safe white light. There are 32 tiny inbuilt cameras and 16 independent sensors with automatic extraction which capture data, density of 600k -1million points in 8-10 seconds. The point accuracy is around 1mm and data point grid is 2×2 mm. The circumferential accuracy is 3mm with a scan volume of 2.1 x 1.2 x 0.6m. It produces comprehensive sets of measurement and further permits measurement extraction profiles to be customised. These are related to: list of measurements, measurement points, body segments, and extra measurements offset from standard landmarks, volume, joints, landmark splicing and so on. It integrates with others CAD applications like Gerber and Lectra and also saves data in various file formats (.rbd, .bin, .ord).

1. Measuring the human body:

3D Body scanning took 8 seconds. The process time took approximately 2 minutes per person in the private scanning booth. During body scanning, structured light patterns projected onto subjects and a series of images are being captured. Then it’s converted to thousands of data points which then corresponded to the shape of the scanned subject. Here, personal space issues are considered by the fact that apart from height and weight, measurement was non-contact and in a private cubicle.

2. Managing and analysing scanned data:

The 3D body scanner is attached to computer with appropriate application which allows visualisation and manipulation of 3D images. Moreover 140 measurements can be extracted within 8-10 sec for each individual full scan by default. The systems are allowed rotation of scanned images, various angles of the scanned data can be further examined. True-to-scale 3D body models with defined measurements are generated and can be printed out. The scanner recorded data in ‘.rdb’, ‘.bin’ and ‘.ord’ files. The file is compatible with others programs like: VMRL, ASCII, Excel, IGES and so on. It is able to automatically load, save data files and export measurement to CAD systems. Hence, exporting 3D data for pattern making, garment draping simulation and 3D body tracking are possible.

3. Benefits of scanned data:

3D Body scanners have excellent advantages in measuring the human body compared to the traditional tape measurement methods. Present possibilities of measuring human body without physical contact are impossible without body scanning. The extensive measurements and human body models can provide a foundation for specified batch and individual pattern construction based on accurate human body measurements. Thereby it’s eliminating observer error in traditional methods.

4. Mass customisation:

Apparel companies continue to go through tremendous changes to create environments where customer requirements are not only met but exceeded. Where it efficiency, productivity, quality, customer satisfaction and competitiveness are critically considered as success factors. Conventional competitive advantages are no longer sustainable. As a result, the emerged business paradigm of mass customisation is being hailed as the solution to problems of fit in the clothing industry. The emergence of 3D body scanning technologies and their integration with CAD systems have presented made-to-measure as viable marketing tool. The mass customisation will overtake standardisation, as consumers’ demand for choice, variety and unique products increase. With passing time, consumers will determine what, when, where and how they want their products. Now, consumers’ demand for more options in shopping of ‘personalised’ products is on the rise. 3D Body scanning are helping to shift the focus of apparel production from mass production to mass customisation with the individualised sizing and design.

3D body scanning for clothing fit:

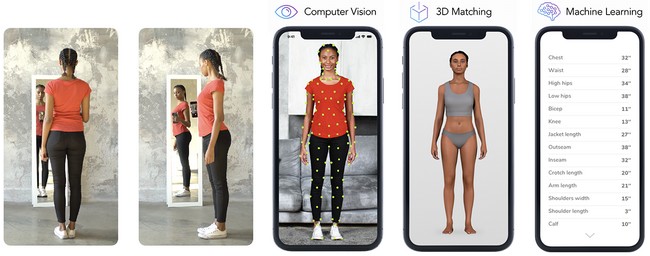

Humans have always been worried about their clothes, look and fittings of clothing. Consumers can be dissatisfied by the complications with clothing sizing and poor fit inconvenience. To solve this problem, 3D body scanners are designed to capture the shape and size of a human body in few seconds. The scanner produces its true-to-scale 3D body model data. The generated data are used to anthropometric dimensions and morphology for the creation of avatars and also manikins. This technology is solving clothing fit problems by generating accurate data according to the development of size charts. The clothing problem will be solved by facilitating virtual model fit trials which also enhance online clothing shopping experiences. Obtaining body measurements using a 3D body scanner is a rapidly increasing in apparel industry because the technology is aimed at reducing the problem of ill-fitting clothes.

3D body scanning in apparel industry:

Producing apparel that match with customers’ will need requires information about the individuals’ body size and shape. 3D body scanning technology utilized to rapidly modify mass-market products is called as mass customization and agile manufacturing. This increases customer satisfaction and decreases inventory costs. In recent times, mass customization has turn out to be an effective tool for the USA based apparel industry.

Adaptation of 3D body scanning in apparel industry has broad future applications areas as follow:

- Standardising sizes, in custom-fitting garments for an individual’s a smart card will able to store an individual’s body measurements.

- Online shopping makes customer visualise for themselves from all possible angles in the form of a personalised avatar.

- Increasing apparel size recommendations system known as made-to measure tailoring.

- In Virtual try on systems, avatar can be virtually dressed with digital clothing, with the option to choose fabric design and colour, and even the accessories such as the trimming and buttons and can make with dynamic poses like walking.

- 3D shape data for avatar creation for online shopping, virtual fit trials, 3D product development, and body dimension analysis for target markets.

- Electronic exchange of information between the pattern-makers and designers without initially making a sample pattern, fabric wastage can be reduced.

- Production of anthropometric manikins based on actual body sizes extracted from data of gender, height and shapes used in apparel industry.

3D body scanning for fashion:

To achieve body scanning in fashion needs true-to-life simulations. The combination of three fundamental elements in industry will make a fashionable product as follow:

- The body shape you want to dress

- The pattern geometry of the model

- The information about the apparel, such as behaviour and visual properties.

Global fashion industry has changed from the era of tailor-fitted apparel to mass-produced garments. Apparel producer can make a positive global fashion impact by embracing the current digital transformation by moving to 3D design technologies. 3D digital technologies in the fashion industry will create far fewer physical samples. As a result, faster production saves times to supply fashionable product to online market. 3D body-scanning technologies are having a growing impact on the fashionable product development, production and whole consumption process in the fashion industry.

Is 3D body scanning the future of fashion?

Yes, 3D scanning technology has the potential to inculcate positive changes in the fashion industry. Optimum utilization of the 3D technology will create a drastic change in the business paradigm. Globalisation is a challenge to the fashion industry where, where customers extensively demand for a wider variety of styles in stores with cost effective and of high quality. But sizing is one of the remarkably toughest problems that trigger the sustainable growth of the whole fashion industry. Only 3D body scanning technology can solve this problem.

Finally it can be said that, 3D body scanning technology isn’t just a technological revolution; it’s a people revolution for the future of fashion.

References:

- Materials and Technology for Sportswear and Performance Apparel Edited by Steven George Hayes, Praburaj Venkatraman

- Garment Manufacturing Technology Edited by Rajkishore Nayak and Rajiv Padhye

- Application of 3D body scanning technology to human measurement for clothing Fit by Phoebe R. Apeagyei Department of Clothing Design & Technology, Manchester Metropolitan University, England,

- Body Scanning and Its Influence on Garment Development by Simeon Gill

- Garment sizing and fit by R. Pandarum1 , W. Yu2 1 University of South Africa, Florida, South Africa; 2 Hong Kong Polytechnic University, Hong Kong SAR, China

- https://www.fibre2fashion.com/industry-article/1693/3d-body-scanning-technology-with-application-to-the-fashion-and-apparel-industry

- https://nomo3d.com/2018/06/04/3d-body-scanning-technology-in-fashion/

- https://www.verdict.co.uk/3d-body-scanning-fashion-future/

- https://www.fibre2fashion.com/industry-article/86/3d-body-scanning-technique-for-apparel

- https://www.sciencedirect.com/topics/engineering/body-scanning-technology

Author of this Article:

Md. Mahedi Hasan

B.Sc. in Textile Engineering

Textile Engineering College, Noakhali.

Email: mh18.bd@gmail.com