What is Yarn?

Yarn is an assembly of substantial length and relatively small cross-section of fibers and or / filaments with or without twist. A yarn is formed via the process of spinning, which takes fibers and twists them. This process holds fibers together (whether they are staple fibers or continuous filaments) and adds strength to them so they are not easily pulled apart.

Different types of yarn occur in the following forms:

- A number of fibers twisted together;

- A number of filaments laid together without twist (a zero-twist yarn);

- A number of filaments laid together with a degree of twist;

- A single filament with or without twist (a monofilament); or

- A narrow strip of material, such as paper, plastic film, or metal foil, with or without twist, intended for use in a textile construction.

In this article I will discuss different types of yarn with pictures.

Different Types of Yarn:

There are four types of yarn structures:

- Spun Yarns which are made from staple fibers,

- Filament Yarns are made from continuous filament fibers that may be monofilament or multifilament;

- Core-Spun Yarns which are often multi-component yarns and

- Compound Yarns which use more than one strand and variations within the structure.

Above four types of yarn are discussed below.

Spun Yarns:

These can be made from short or long staple fibers. Short fibers are under 60 cm in length, whereas long fibers are between 60 cm and 120 cm in length. The yarns produced generally have excellent handle, feel good next to the skin, have reasonable strength and uniformity. In the raw state, the surface of the fabric is matt because light cannot reflect off it naturally due to the slightly hairy projections of the ends of the fibers that stick out. Of course, certain fabric finishes can alter these properties.

Filament Yarns:

These can be either flat or textured. The former have some level of twist to hold the long, parallel fibers together (to prevent snagging or breaking), and textured yarns are shaped with crimps and loops to add bulk and texture to the fabric. Fabrics using filament yarns have excellent strength and can be very fine. A flat-filament fabric often has a smooth, shiny surface because light reflects off it easily.

Unfortunately, though, it usually has poor resilience. A textured-filament fabric, by contrast, often has fairly good resilience due to the crimps and loops it possesses.

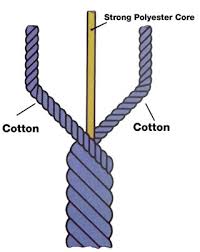

Core Spun Yarn:

This yarn has an outer wrapping of fibers around a central core of yarns. Quite often the outer wrapping is made out of a different fiber than the central core – for example, stretch fabrics have an inner core of elastane (Lycra) and an outer cover of a non-elastic fiber, such as cotton. These multi-component yarns are usually stronger due to the outer wrapping of the fibers, more uniform and fuller than other ring-spun yarns. These yarns are used often in both knitted and woven fabrics, especially where greater elasticity is required.

Compound Yarns:

Previously mentioned yarns are single-strand yarns but when more than one strand can be used they are called compound yarns; these can be further classified into ply, cabled or fancy yarn.

a. Ply yarn:

Some call this folded yarn. It is a combination of two or more strands that are twisted together to ensure the correct use of the S and Z twists so the yarn will stay together. This yarn can lend greater strength and durability to a fabric when used e.g. men’s shirts and hand-knitting yarns.

b. Cabled yarn:

Two sets of plied yarns are twisted together to produce a bulkier yarn.

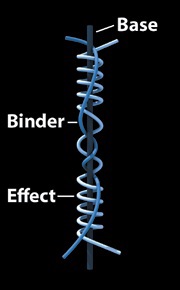

c. Fancy yarn:

This yarn can be made during the spinning process, and it can provide a wide variety of textures and colors to the yarn. The basic components of fancy yarn are the base (or core), the ‘effect’ yarn, and, sometimes, a binder to hold everything together.

Adding a variety of colors to the textured yarns lend a mottled or marbleized effect to the fabric, whereas combining matt and luster effects with the fibers produces fabrics such as Lurex. However, the durability of these yarns is not as good as the uniform-spun yarns.

Slub Yarns:

These are either single or folded yarns that have thicker areas where the fibers are usually more loosely spun at regular or irregular intervals along the length. The fabrics may look like linen.

Boucle, Looped or Curled Yarns:

These are compound yarns that are specially processed to form loops along the length. Fabrics have a rough handle and a fair amount of texture on the surface. They have at least two strands: one tensioned and plied, whilst the other one is looser forming the loops.

Chenille Yarn:

This has a center core of two twisted yarns, often made of cotton, with fibers projecting from it, which makes it soft. Light will reflect differently from various angles due to the projecting fibers.

Corkscrew or Spiral Yarn:

Two different fibers are twisted together, often at different tensions.

Knot or Nub:

Made when the effect yarn is twisted tightly around the core.

Metallic Yarns:

It is classed as a fancy yarn, but a metallic fiber is added to the blend.

Crêpe:

It can also be classed a fancy yarn made by over-twisting, which causes the yarn to loop and kink.

Complex or core-spun yarns:

These yarns are made with a central core of one fiber around which is wrapped or twisted an exterior layer of another fiber. Core-spun yarns may be made with elastomer core, such as Spandex, covered by another fiber to produce a stretch yarn. Other core-spun yarns include sewing thread made with a polyester core and cotton cover, suitable for high speed industrial sewing processes in which 100% polyester thread could melt due to the high temperature that the sewing needle may reach.

Textured Yarns:

Textured yarns can have high stretch, high bulk, or air-jet bulk, which is produced from filament fibers at various stages during their production from undrawn, partially drawn, or fully drawn fibers. The majority of these yarns are made of fully drawn fibers, mainly polyester or polyamide.

Stretch Yarns:

These can be made in five different ways:

1. Heat setting:

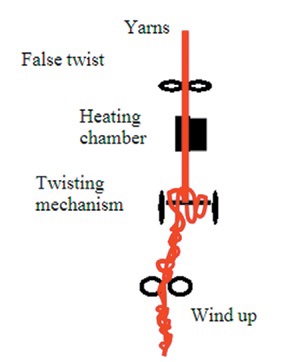

Using the thermoplastic property of the synthetic fiber, they are shaped into coils, crimps, curls, or waves.

- Coils can be achieved in a number of ways, but the most popular method is placing a false twist – essentially, a high twist is placed into the fiber, which is heat set with steam and cooled quickly. Untwisting it causes the fiber to coil and act like a spring. This is used for tight fitting products e.g. tights, stockings, ski pants and swimsuits.

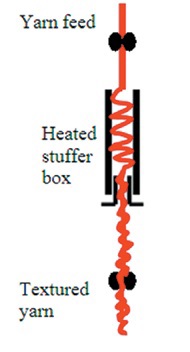

- Crimps are produced in a number of ways. One method entails using a stuffer box: the filaments are stuffed tightly into a heated chamber (the stuffer box), which changes the shape of the yarn into a random zigzag pattern or uses two cogged wheels opposite each other to crimp the yarn after extrusion.

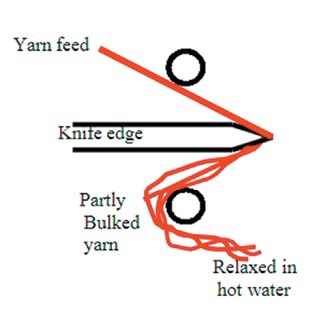

- Curls can often be produced by pulling the fiber against a flat blade and then relaxing it in hot water to produce a gentle curl. It is used in hosiery, crêped fabrics, lingerie, fleece and fur.

- Waves are created by knitting the yarn, heat setting the fabric, and then unravelling it. This process is known as knitde-knit.

2. Elastomeric Yarns:

These are made of rubber or elastane. A center core of the elastomeric yarn is wrapped with another fiber.

3. Bi-Component Yarns:

These are made from two different types of man-made fibers, e.g. polyamide 6.6 with polyamide 12, being extruded through the spinneret at the same time. Their setting and shrinkage rates are different, which causes one of the yarns to pull more than the other, causing the yarn to distort into a crimp or spiral.

4. Bi-Constituent Yarns:

These use two different types of polymer, e.g. Lycra with polyamide, being extruded through the spinneret at the same time.

5. Chemically Treated Natural Fiber Yarns:

Cotton fibers are treated with resins or chemicals with thermoplastic properties and then treated in a similar manner to that of heat setting. However, due to the nature of cotton, the spring-like action is slow, and it may only return to 75% of its original shape until it has been washed. Slack mercerization of the cotton fabrics allows the fabric to stretch with 80% retention of the original size at first and full retention after washing.

Bulk Yarns:

These are thick, soft yarns that stretch.

1. High Bulk:

These are crimped staple fibers, usually made of pure acrylic or acrylic blended with other fibers and spun with a slack twist. Also, it may be blended using fibers that have been stretched and then relaxed. When these yarns are dyed, the stretch fibers relax, causing the relaxed fibers to crimp and curl. This process results in a thick, lightweight and soft yarn. These yarns have air pockets, so they trap air and absorb water, making them suitable for blouses, sweaters, etc.

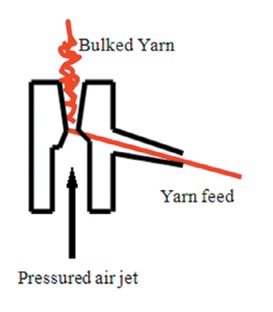

2. Air Jet Yarns:

These are also known as loop-bulk yarns. Using continuous filaments such as acetate, polyester, polyamide and viscose, the yarn passes over high—pressure jets of air that cause the fibers to loop and become tangled. They are bulky but lightweight, and they will absorb moisture due to the gaps between the loops. Notably, however, they have little elasticity because the loops are set. These yarns are used mainly in woven fabrics to give surface texture.

Cabled or cord yarns:

This yarn is obtained by twisting together a multiple (i.e. multifold) of yarns. This types of yarn is mostly used in the tire industry and is designated as tire cord. It is manufactured to exhibit specific properties. Another example of the end use of this type of yarn is as a sewing thread. The performance of this yarn in the examples cited could not be obtained by any other yarn types, since the major properties provided are its strength, tensile modulus and elongation.

References:

- Fibres to Fabrics By Bev Ashford

- Textile Engineering-An Introduction Edited by Yasir Nawab

- Advances in yarn spinning technology Edited by A. Lawrence

You may also like:

- Fancy Yarn: Types, Properties, Manufacturing Process and Application

- What is Yarn Twist | Twist Direction | Twist Level

- Yarn Count System and Determination by Different Methods