What is Singeing?

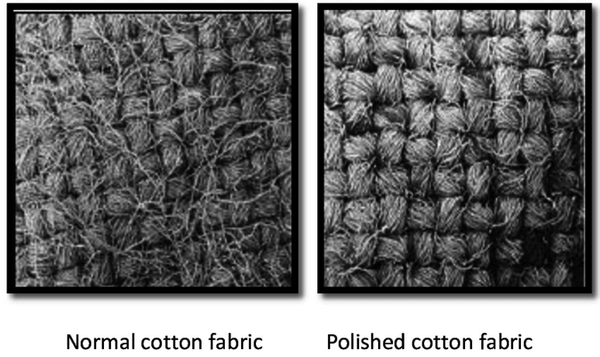

In the weaving process, the warp yarns pass through the heald wire and reed of the loom. During this process some of the fibers move outwards the surface of the yarn i.e., the yarn develops hairiness due to the constant friction between the heald wire and yarns, these are called projecting/floating fibers. Simply, singeing is the process of removing floating/projecting fibers from the surface of the fabric by burning; as a result the fabric becomes smoother, increase luster and also prevents pilling.

Purposes of Singeing Process

The main purpose of singeing is to remove floating fibers from both sides of the fabric. For this purpose, the exposed end of the fabric is sent through a singeing machine with a certain tension. Here are some important and common purposes:

- The main purpose of this process is to remove small floating fibers from the surface of the yarn or fabric.

- To make the fabric smooth; As a result, the shade looks better after dyeing.

- To increase the brightness of the fabric.

- To make the pill resistant so that it does not form while wearing clothes.

- To make the fabric or yarn suitable for the next process.

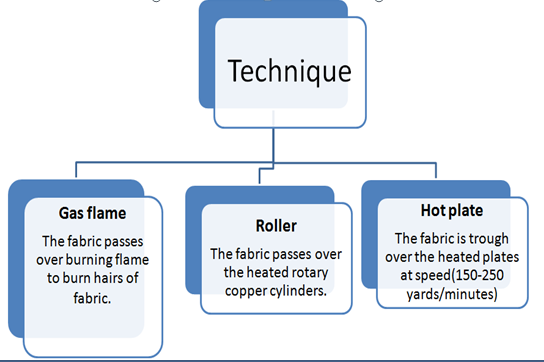

Different Methods or Techniques of Singeing Process

In the singeing process, three separate techniques can be applied to remove floating fibers from the surface of the fabric. At the end of each process, the fabric becomes smoother than before and its luster increases.

Name of the machine used in the singeing process:

- Plate Singeing Machine.

- Cylinder/Roller Singeing Machine.

- Gas/flame Singeing Machine.

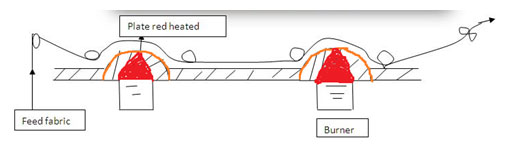

A. Plate Singeing Machine

- In the process of plate singeing, the plates are heated with the help of certain fuels (combination of air and gas), when heated, it turns reddish.

- Then the fabric is passed over two heated curved plates at a fixed speed (135-225 meters per minute).

- The thickness of these plates is 1-2 inches.

- However, in this process, one side of the fabric is completed. To do the singeing on the other side, again in the same way the other side of the fabric has to be passed over the heated plate.

Advantages:

- The friction of the heated surface and the fabric produces a small amount of luster.

- Uniform singeing

- Good for Velvet and Pile fabrics.

Disadvantages:

- It is difficult to control the temperature of the plate.

- Only one side of the fabric is singed.

- It takes more time.

- Uniform singeing is not done in the stitch part.

B. Cylinder or Roller Singeing Machine

- In this type of singeing machine, the fabric is passed over the surface of the heated cylinder made of copper or cast iron.

- The inside of the cylinder has a firing system so that it heats up and rotates it slowly so that certain heated surface of the cylinder comes in contact with the fabric. It burns the floating fibers in that part of the fabric and makes the fabric smoother.

- This type of singeing machine is suitable for velvet and pile fabrics.

- In this type of process one side of the fabric is singed. If singeing on both sides of the fabric is required, two cylinders are added, one for each side of the fabric.

Advantages:

- The surface temperature of the cylinder is more uniform than plate singeing process.

- Convenient for Velvet and Pile fabrics.

Disadvantages:

- Only one side of the fabric is singed at a time.

- Uniform singeing is not done for very wide fabrics.

- If the singeing process will not perfectly done, after dyeing some fuzzy stripes can be seen on that fabric.

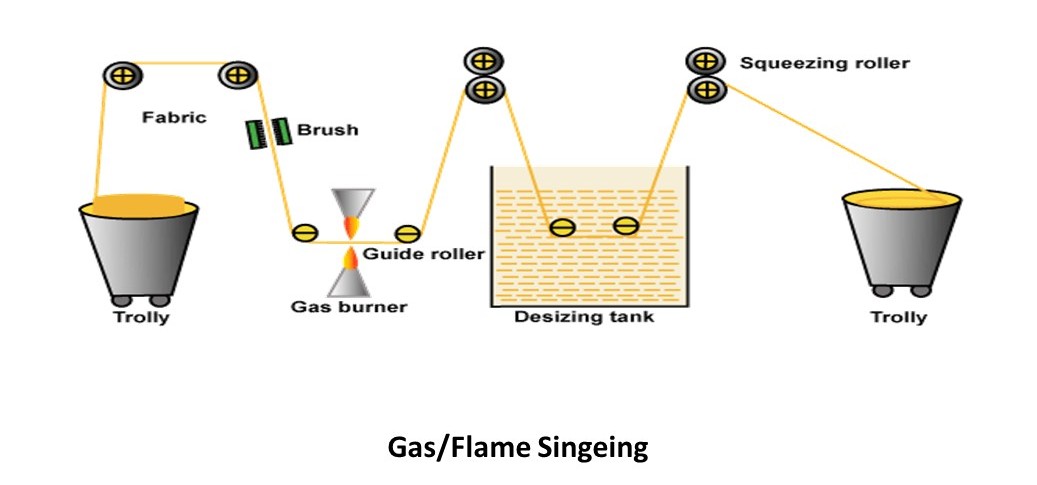

C. Gas/Flame Singeing Machine

- This machine uses one or more burners to provide continuous vertical fire flame and the mixture of air and gas (Natural gas, LPG, Butane etc.) is used as fuel in this flame production, hence this process is called gas/flame singeing.

- First the exposed edge of the fabric is passed through the brushing roller. As a result, the attached floating fibers of the fabric become separated.

- Then at a certain speed the fabric is sent over the flame of the burner, then the floating fibers are burned. There are different types of machines based on the design of the burner.

- In this type of singeing machine, the fabric passes over the flame at high speed. Only the floating fibers are burned, which does not cause any damage to the fabric.

- The width of the burner can be adjusted to the width of different types of fabrics. For different types of fabric, the flame height and heat intensity need to be controlled.

- The maximum flame temperature of these burners is 1300°C.

- In this type of machine, the speed of the fabric is kept at 200-250 meters per minute. This speed limit depends on the types of fabric.

- This type of machine is connected to the water tank, after the singeing process, the fabric is immersed in this water tank or sprayed with water, so that the fabric is not damaged by the sparks.

- In this method singeing is done on both sides of the fabric.

Important parameters:

- Burner temperature: 1250-13000C

- Burners flame speed: 15-35 m/s

- Flame intensity: 5-20 bars

- Fabric speed: 200-250 m/min

- Width of flame: equal to the width of the fabric.

- The distance of the fabric from the flame: usually 6-8 millimeters.

Advantages:

- Maintaining uniform temperature results in uniform singeing.

- It is possible to singed both sides of the fabric at the same time.

- Temperature or flame speed can be easily controlled.

- It is possible to do more fabric singeing in less time.

Disadvantages:

- If the burner is dirty, black spots may appear on the fabric.

- Not convenient for synthetic fabric.

- If the speed is not maintained well, there is a possibility of burning or over-singeing of the fabric.

Why Gas Singeing is More Popular than Plate and Cylinder Singeing?

- The projecting/floating fibers burn better in gas singeing than in plate or cylinder singeing.

- Uniform singeing can be done by gas singeing m/c, which is not possible in plate or cylinder singeing m/c.

- The smoothness and brightness of the fabric is higher in gas singeing than in plate or cylinder singeing.

- The speed of gas flame can be changed according to the types of fabric.

- Production is more in gas singeing than plate or cylinder method.

- In gas singeing m/c, singeing is done on both sides of the fabric, on the other hand only one side is done in plate and cylinder method.

- Uniform temperature can be maintained in gas singeing.

- Gas singeing process does not generate excess lusters in the fabric.

Due to the above advantages, gas singeing is more popular than plate or cylinder singeing methods.

The Following Precautions Should Be Taken during the Singeing Process

- The fabric must be dry before singeing because wet fabric is more likely to get scorched when singeing.

- Make sure that the fabric does not contain any kind of acid releasing salts, because when the fabric is heated, acid can be released.

- Burners should be kept clean regularly; otherwise black spots may appear on the fabric.

- The speed of the machine should be controlled so that the cloth does not burn.

- As a result of singeing, the fabric may become a little stiff, because size (starch) material is present in the warp yarn of the woven fabric. So, singeing should not be done for a long time.

- In case of temperature sensitive fabric, the temperature should be controlled properly otherwise the thermal properties of the sensitive fabric may be lost. Fiber can be easily burnt, which can damage the fabric. This process causes small balls to form on the fabric surface as the fibers melt in the case of heat sensitive fabrics. So, when weaving this type of fabric, you have to work keeping in mind the thermal properties of the fabric.

Bio-Polishing:

We usually understand singeing by burning woven fabric but now singeing is also done on knit fabric and it is done in a complete chemical process. Cellulase enzymes are used in this chemical process to remove floating fibers from the knit fabrics. This process is also called biopolishing or enzyme wash as it is done with the help of bio-chemicals. The basic difference between them is that singeing is a mechanical & thermal process but bio-polishing is a wet process.

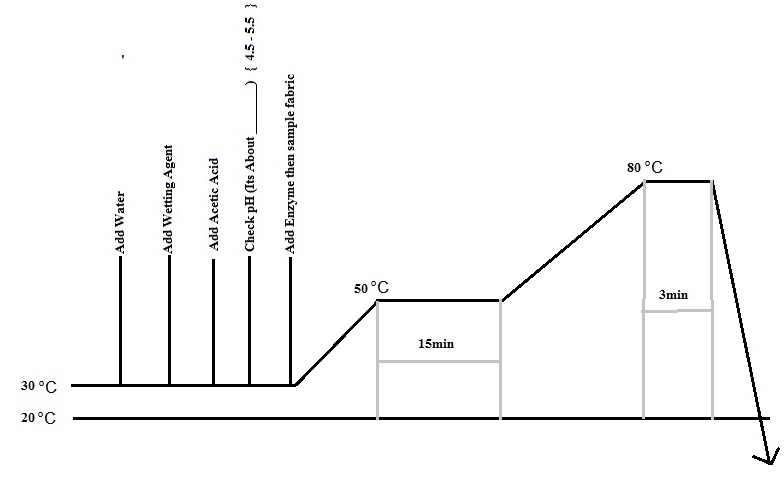

Some Conditions and Recipes of Bio-Polishing:

- Cellulose enzyme: 1-3%

- Wetting Agent: 0.5-1.0 gm/L

- Acetic acid: 0.5 gm/L

- pH of Batch: 4.5-5.5

- Temperature: 40-500C

- Time: 45-55 min.

- M: L: 1:10

Mechanism of Bio-Polishing:

Cellulose enzymes are located in acidic (pH = 4.5-5.5) medium and at certain temperature break down the cellulose of the fiber floating from the surface of the fabric into water soluble glucose. This is how the hairiness of the fabric is removed. However, processing time is a big issue in case of enzyme washes or biopolishing, because if enzyme washes are done for a long time, the floating fiber may run out and damage the yarn. So, by continuous follow-up and checking the samples, the washes should be kept running till the floating fiber is removed.

Advantages:

- The process can be completed at low cost.

- Improves the quality of the fabric.

- Convenient for cotton fabric because even the micro fibrils of cotton can be removed.

- The surface of the fabric is clean.

- It takes less time so the production is more.

Disadvantages:

- Eliminates less hairiness than singeing.

- Only cotton fabric can be processed.

Difference between Singeing and Biopolishing

| Singeing | Biopolishing |

| 1) Singeing is a mechanical process. | 1) Biopolishing is a wet process. |

| 2) More hairy fiber removed | 2) Less hairy fiber removed compare to Singeing. |

| 3) No need of enzymes, wetting agents or any other chemicals. | 3) Need enzymes, wetting agents and other chemicals. |

| 4) High speed process. | 4) Low speed process. |

| 5) Costly process. | 5) Cheap process. |

| 6) Increase luster. | 6) Decrease Luster. |

Testing the Effectiveness of Singeing

After the singeing is done, it must be checked whether the uniform has been singed. Can be tested in different ways, such as-

- Magnifying Glass, without singeing and singed fabric can be compared. Synthetic fabric will show much less hairiness.

- Pilling Test can also be tested.

- The hairiness of the fabric can be checked with the help of Sticking Tape.

- Also with the help of Hand Feel, it can be checked whether the fabric is uniformly singed.

Conclusion

Singeing is an important step in the pretreatment process. It is a process of removing projecting / floating fibers. This singeing process is mainly done to smooth the fabric and increase its brightness & luster. Singing is done only in the case of woven fabric. But in the case of knitted fabrics, this process is called biopolishing, where enzymes are used to remove these floating/projecting fibers.

Author of this Article:

Md. Imran Hossain

B.Sc. in Textile Engineering

Shahid Abdur Rab Serniabat Textile Engineering College, Barisal.

Email: mdimranhossain.te@gmail.com