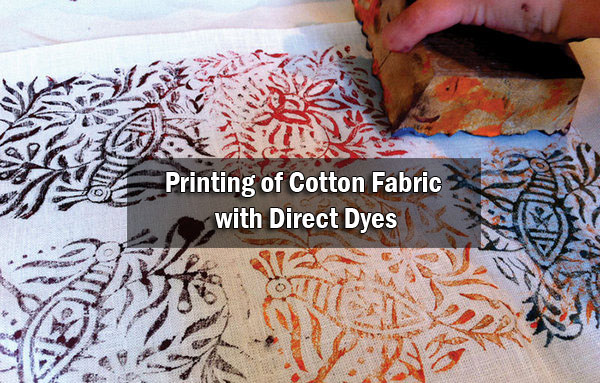

Name of the experiment: Study on Printing of Cotton Fabric with Direct Dyes

Introduction:

Textile printing is the art of design by mechanical and chemical application. It is the localized application of dyes or pigments by a method which can produce attracting design or particular effect of color on the fabric according to design. Printing is the process for producing a pattern on yarns, warp, fabric or carpet by any of a large number of printing methods. Printing has always been an important process for producing fashion effects on cotton fabrics. It is estimated that around 50% of all printed fabric is 100% cotton.

Theory:

Printing of cotton fabric with direct dyes by direct and discharge styles. These dyes have generally poor washing fastness, which is of particular disadvantages since during the removal of the exhausted thickener film from the fabric after steaming, the residual dye present in the film as well as part of the dye which is already fixed in the fabric bleed out into the rinsing water. In this case the production of absolutely white ground becomes difficult.

You may also like: Different Types of Dyeing Methods

Two approaches have been followed to counteract this tendency of staining the white ground. In one an optical brightener is applied from the last rinse so that a dazzling white ground may be produced. In the other a cationic dye fixing agent is applied before the after wash.

Methods:

Direct dye is used for printing and hand screen in screen printing method is used.

Apparatus:

- Beaker

- Glass rod

- Measuring Flasks

- Bowl

- pH meter

- Burner

- Thermometer

- Digital balance.

Recipe for printing:

- Dye = 30 gm/ kg

- Water = 300 cc/ kg

- Urea = 25 gm/ kg

- NaHCO3 = 50 gm/ kg

For pest formation,

- Starch = 8 gm

- Water =100 cc

- Time = 5 min

- Temperature= 70-80°C

Then stir properly until the required viscosity is form and cool the pest.

Recipe calculation:

- Dye=3%

- Water=19.55

- Urea=2.5%

- NaHCO3=5%

- Thickener=70%

Chemicals and its function:

| Chemicals | Functions |

| Dye (direct dye) | Main color producing agent containing chromophore group. |

| Urea | It is a dispersing agent, use to get bright design and assist dye penetration. |

| NaHCO3 | To control the pH |

Procedure:

- Firstly thickener was produced by 100 cc water and 8 gm of starch.

- The solution was made by required chemicals and water.

- After that thickener was added with that solution,

- Then solution was stirred

- After that solution was felt into a screen with pressure.

Result:

Printing is the most important process of fiber processing as well as textile goods now a day. By this experiment we come to know about the printing process of cotton fabric, especially the use of direct dyes in printing. We also know the recipe and controlling points of using direct dye.

You may also like: Dyeing of Jute Fabric with Basic Dyes