Geogrid: Types, Structures, Installation and Application

Anam Saleem

Department of Textile Engineering

University of Managment and Technology, Lahore, Pakistan

Email: 111811017@umt.edu.pk

Introduction:

A geogrid is geo synthetic material used to reinforce soils and similar materials. Geogrids are commonly used to reinforce retaining walls, as well as sub bases or sub soils below roads or structures. Soils pull apart under tension. Compared to soil, geogrids are strong in tension. This fact allows them to transfer forces to a larger area of soil than would otherwise be the case. Geotextiles are manufactured for separation, filtration, and drainage purposes, whereas geogrids are specifically manufactured as a reinforcement material.

Geogrids are commonly made polymer materials, such as polyester, polyethylene or polypropylene. They may be woven or knitted from yarns, heat-welded from strips of material or produced by punching a regular pattern of holes in sheets of material, then stretched into a grid. These products are flexible, very durable, and have long-term design strength. Geogrid reinforcing is designed to be used in conjunction with retaining wall block and soil to stabilize the mass behind the wall.

Geogrids are flexible, synthetic meshes which are manufactured specifically for slope stabilization and earth retention. Grids are available in a variety of materials, sizes and strengths. They can be made of high tensile strength plastics or woven polyester yarns, and are typically packaged at the factory in rolls. The grids are rated by Long-Term Allowable Design Strength (LTADS) with values ranging from 500 to 3,000 pounds per linear foot (7.3N/m to 43.8N/m).

Working with Geogrid:

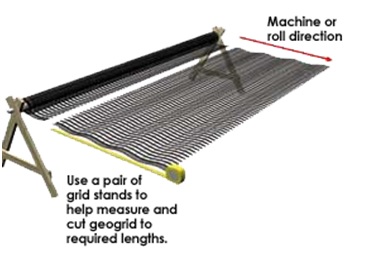

Geogrid typically comes in large rolls up to 13 ft (4 m) wide and 250 ft (76 m) in length. These “grids” also come in a variety of weights and strengths. Taller walls often require heavier strength grids, especially in the bottom portions of the wall. Most grids are strongest along the roll or machine direction. Reinforced grid designs require that all grids are placed with the machine direction running from the face of the wall towards the back of the excavation area.

Geogrid Installation:

Installation steps are

Step 1: Excavate reinforced soil area.

Remove existing soils in the reinforced soil area to the maximum embedment length of the geogrid design. Provide a generally level soil condition behind the wall units for the placement of each geo-grid layer.

Step 2: Cut Geo grid.

Cut sections from geo-grid roll to the specified length (embedment depth). Geo-grid roll direction is from the wall toward the embankment (check manufacturer’s criteria). In most cases correct orientation is to roll the geo-grid perpendicular to the wall face.

Step 3: Install Geo grid.

Hook geo-grid over the fiberglass pins to ensure a positive mechanical connection between the unit and geo-grid

Step 4: Secure Geo grid.

Pull the pinned geo-grid taut to eliminate loose folds. Stake or secure back edge of geo-grid before and during backfill and compaction. Remove stakes, if desired, once backfill is placed. Place additional sections of geo-grid, abutting each other, for continuous coverage at each layer.

Step 5: Install next course of Keystone units.

Check for level with each new course.

Step 6: Place compacted backfill over geo-grid in 8” lifts.

Provide a minimum of six inches reinforced fill coverage prior to driving equipment over the geo-grid with wheeled or tracked equipment. Avoid driving or turning equipment directly on geo-grid to avoid excessive damage.

Structures of Geogrid:

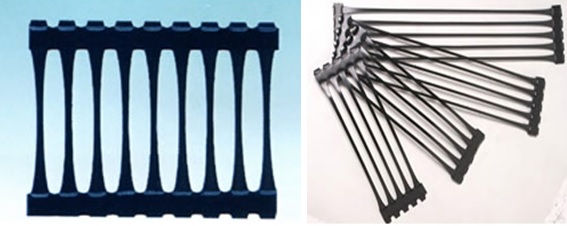

1. Unidirectional geogrids

Unidirectional geogrid is extruded by macromolecule polymers, and formed by longitudinal tension. This kind of geo grid is integrity with uniform distributed elliptical net structures. It has high tensile strength and tensile modulus. With this kind of structure, the geo grid provides an ideal interlock system for the soil. It has high unidirectional strength and endurance, and high lateral restraints for soil-rock mixtures. All property indexes of it are superior to geo grid without tension. It is an ideal reinforced material at present, such as reinforced earth structures in reinforced retraining wall, reinforced steep slope, bridged abutment and highway, railway and airport.

The Benefits:

- Wide range of facing options (Concrete blocks, concrete panels, treated timber in various textures and colors)

- Overall savings up to 60% on material and time when compared to conventional reinforced concrete and gravity structures.

- High resistance to dynamic shock loading and seismic activity.

- Allows the use of on-site-available fill

- Fast, easy and economical construction

- Withstands differential settlement

- High connection capacity strength between facing and the grid

- Aesthetically appealing structure

- Reduction of traffic disruption and lane closure

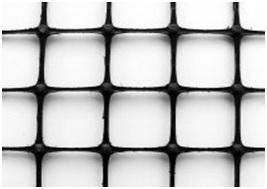

2. Biaxial (BX) geogrids

The material of biaxial geogrid is similar with the material of unidirectional geogrid. Its chemical property isn’t active too. It is extruded by macromolecule polymers, and formed by longitudinal and horizontal tensions. This kind of material has high tension strength in both longitudinal and horizontal directions. This kind of structure provides a interlock system for the soil and is suitable for the improvement of roadbed with large area permanent load, such as treatment of soft soil foundation and reinforced earth structures.

The Benefits:

- Cost savings with major performance benefits

- Considerable savings in granular thickness without compromising performance

- Control of differential settlement and rutting

- Great Improvement of Traffic Benefit and Layer Coefficient ratios

- Prevention of upward movement of the subgrade fines by pumping

- Achieving longer pavement life cycle

- Minimize undercutting and backfilling

- Increase the effective bearing capacity beneath shallow spread footings

- Avoids the requirement of pile caps, vibro concrete columns, concrete rafts, stone piles etc., otherwise needed for the conventional alternatives in foundation support applications.

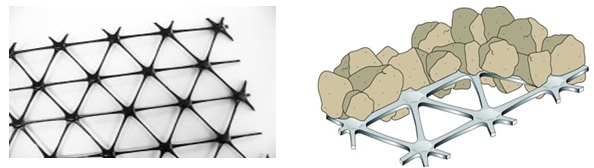

3. Triaxial geogrid

Triaxial is a revolutionary new geo grid product. The triangular structure of triaxial geogrid, coupled with the increased rib thickness and junction efficiency, greatly improves aggregate interlock and confinement – leading to optimal structural performance of the mechanically stabilized layer. Research indicates that triaxial geogrid can reduce aggregate base/sub-base requirements by 25% to 50%.

Triaxial geogrid delivers performance in three dimensions:

- Multi-directional Load Distribution

- Multi-directional Load Distribution

- Junction Integrity and Efficiency

- Superior Performance for Paved and Unpaved Roads

- Less Stress on Sub grades

Types of Geogrids:

1. Fiberglass geogrid:

Fiberglass geogrid is a new excellent material used for reinforcing road surface and base, it made by fiberglass filament, and covered by special solution. High longitudinal and horizontal strength, low elongation rate, anti-alkali and aging resistance, widely used in asphalt road surface, concrete road surface and reinforcing road base.

2. PET Geogrid:

Terylene geogrid is a new material for reinforce road base, it made by terylene filament, and covered by special solution. High longitudinal and horizontal strength, low elongation rate, anti-alkali and aging resistance.

3. Warp Knitted Fiberglass Geogrid:

It is woven by high Tensile Modulus fiberglass filament as the raw material coated with adhesive.

Properties:

- High tensile strength in warp and weft directions

- Low stretch rate

- Excellent temperature range adaptability

- Has excellent UV, alkali and oxidative resistance, which result in exceptional aging

- To eliminate the problem of pavement cracking on highways, roads and runways, and driven by the need to reduce costs for infrastructure maintenance and repair.

4. Plastic Welding grill:

It is the company based on market demand, self-developed high-strength geogrid. Plastic welding geogrid is a polypropylene-based material, by adding anti-aging agent and other additives, by extrusion stretching into the rough surface of refined embossing of high-strength rib to rib by plane at right angles, by ultrasonic welding made its point of intersection. Applicable to reinforced earth retaining wall abutments, steep slopes, soft-based projects such as the reinforcement, reinforcement. Color of the product according to customer requirements.

Technical characteristics of products:

- High intensity;

- Bending folding, good anti-fatigue, anti-corrosion, continuous rolling;

- The role of soil friction force Yin large, wide application scope, it is suitable for high-load engineering use.

Curves with Geogrids:

Inside Curves:

Geo grid needs to have 100% coverage around an inside curve. To achieve this, additional layers need to be installed either above or below the course where the grid is required to fill voids that are created.

- Cut geogrid to required lengths per the approved plan.

- Lay out the primary geogrid around the curve butting front edges together. Make sure strength direction runs perpendicular to wall face. Mark the blocks or take note of the areas where there are voids in the grid placement.

- Place the filler piece of grid on the next course (or the course below) to cover the void left on the primary layer.

Outside Curves:

- Cut geogrid to required lengths per the approved plans.

- Lay out the geogrid around the curve.

- Lift the section of grid that overlaps and place the fill material to separate. Grid layers need to be separated by a 3 in. (75 mm) layer of approved fill material.

- Never compact directly on the geogrid.

Application of Geogrid:

- Airport runways, taxiways, aprons.

- Highways and toll plazas

- City roads and traffic signal junctions

- Industrial roads, SEZ

- Parking lots, bridges, asphalting on distressed PCC surface

- Mining

- Landfill

- Golf and sport fields

You may also like:

- Geotextiles: Types, Properties, Functions, Applications & Market

- Application of Nonwoven Geotextiles: Challenges and Opportunities

- Sustainable Applications of Geotextiles in Civil Engineering