The textile industry of Bangladesh is the largest contributor about 11.49% to GDP about 84.21% of total export in last 2019 fiscal year. This textile industry has increased in tremendous amount since 1978. The growth of the textile sector has leaded Bangladesh to become one of the middle earning countries of the world by 2021. But this sector has always faced some problems. The most serious threat to this sector is its backward linkages.

What is backward linkage industry?

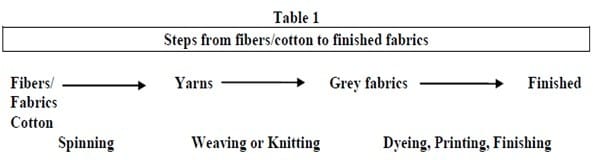

Generally, backward linkage means the use by one firm or industry of produced inputs from another firm or industry. That means in the textile industry, finished textiles depends on three steps. These are:

- The first level first converting fibers or cotton to yarns,

- second step for converting yarns to grey fabrics

- final step for converting grey fabrics to dyed, printed of other finished fabrics/apparel.

There are three steps are integrated into each other as shown below. Out of these three steps, Bangladesh is only capable of knitting, finishing in knitwear.

Backward linkages sub-sector of textile industry:

1. Cotton:

Cotton is the main source of making yarn and fabric. But cultivating of cotton requires a vast amount of land. But Bangladesh is a small country which does not have vast amount of lands, and also need special kind of soil to produce good cotton which Bangladesh does not have.

The farmers find cotton farming less beneficiaries in Bangladesh. Therefore, they move on to different fiber materials. This is why Bangladesh has to depend on other countries like Uzbekistan, India, China, Pakistan, America, Egypt, Turkey, and Australia for cotton.

2. Spinning mills:

Where the yarn is created from fiber that’s are Spinning mills. It is very important section of textile industry it is where yarn is created for sewing, weaving and knitting. The main products of spinning are mainly cotton yarn. Raw material is still under managed and unfocused, which is roughly about 60% of cost of goods sold. And then is the productivity of our mills that is still minimum 10% less than the competing countries like Vietnam, India, Pakistan, China. Raw material and productivity alone can show the light to improve margin of spinning sector.

3. Weaving:

The process of making woven fabric is called weaving. Woven fabric manufacturing condition in Bangladesh is not so satisfactory. Because of the woven is very costly in textile industry. To set a minimum woven composite factory, it will take $35 million dollars. To run this sector and maintain the buyer requirement a huge amount of fabric is imported from China, Vietnam and others country. After getting the order first the textile industry has to search for reliable source to import the fabric and yarn. This importing of woven fabrics cost 75% which is the total amount of an order cost. This takes away a lot of money of the Bangladesh.

Today, there is more than 4321+ woven factories which are registered in BGMEA. But, according to the BTMA the number weaving mills in Bangladesh is 302 which is very low according to the registered number of woven factories.

4. Knitting:

The process of making knit fabric by inter-looping of yarn is called Knitting. Knitting industry in Bangladesh is the leading market contributor of textile industry. Because of the low costs machineries knitting and available up gradation this industry has merged in huge amount. There are lot composite knit garments industries in the last decade in Bangladesh.Bangladesh knitwear industry provides various extremely value-added quality full products which demands are full in western countries.

5. Trims & Accessories:

As the textile industry grows rapidly the demand of raw-materials grew in enormous form. Bangladesh trims and accessories industries are very much top level. It maintains the demand fully and provide value added service and products. The quality of trims and accessories produced in Bangladesh is very tremendous.

Since the growth of textile industries, the trims and accessories industry become very much sufficient. Today, Bangladesh has more than 1400+ trims and accessories industry in Bangladesh meeting the challenges provided by the global market and providing the best quality full products. Member growth of Bangladesh Garments Accessories & Packaging Manufacturers & Exporters Association (BGAPMEA) are given in above chart.

Problems of backward linkage in textile industry:

The backward linkage in textile industry of Bangladesh in RMG sector is 5-8% to the total demand. For this reason, the raw-materials like fabric, trims and accessories are being imported from other competitive countries. As a result, a huge amount of raw-materials are being sourced from foreign market.

To purchase this raw-materials 60-70% of product price go away in overseas market and the profit gain from these production orders is very less. Purchasing the raw-materials from other countries takes a lot time.

Now the most of the raw materials has to import from abroad like China, Vietnam. It takes time to get the raw-materials in time and also start able production. Though Bangladesh has to reach huge success to upgrade their backward linkage industry over the decade still they have to depend on overseas market.

If the demand of the raw-materials in textile sector like fiber, yarn, fabric, trims and accessories can’t be made up by the domestic market this industry will face many problems in the future.

Recommendation for backward linkage:

Present condition of backward linkages impact on Bangladesh textile industry in future. The accomplishment of the textile industry very much depends on effective control over the supply of raw materials components. From the fibre to finished apparel, all steps involved with: spinning, weaving, finishing accessories. These are the integral parts of backward linkages. The alternate support of the central bonded warehouse is critical unless backward linkage satisfies itself, in each sector by its component, especially within the spinning and weaving sector.

Firstly, we need to analyze the current condition to reduce cost of production backward linkages. Need to development on effective marketing service strategies that provide right signal of raw materials.

Conclusion:

The textile industry of Bangladesh has become the gold giving eggs in the context of Bangladesh. After the independence of the country revolution the textile industry has a lot of effort.

Now a days, this textile industry has become the biggest earning source of the country. So, this textile industries development is very important in self-reliant of the country. But the weakness of backward linkage in textile industry in Bangladesh, possessing a huge threat to the growth of this sector.

The Textile industry of Bangladesh is facing dramatic problems of meeting the demand of the buyer because of the lacking in the backward linkages industries. If the textile industry falls, the countries development would be hampered in huge quantity. So, we believe that, the people of the country understand the value if this industry takes necessary step.

Author of this Article:

Md. Mahedi Hasan

B.Sc. in Textile Engineering

Textile Engineering College, Noakhali.

Email: mh18.bd@gmail.com