What is Acrylic Fiber?

Acrylic fiber is a synthetic fiber made from polymers primarily composed of polyacrylonitrile, a petroleum-based polymer which was first made in Germany in 1893 but not considered a textile fiber until 1944 when DuPont developed it as a commercial fiber called Orlon; this was ready for production in 1950. Monsanto developed another acrylic fiber called Acrilan in 1952, and by 1958, another form of acrylic was produced; Creslan. Acrylic fiber is known for its wool-like feel, durability, and bright color. So it is called artificial wool.

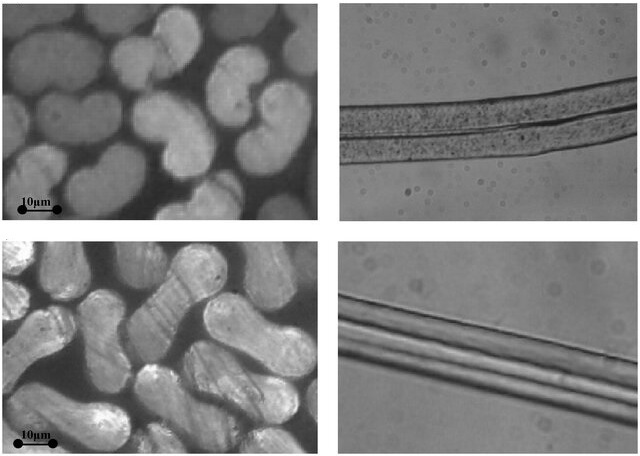

Microscopic and Longitudinal View of Acrylic Fiber

Properties of Acrylic Fiber

- Absorption: Acrylic has low absorbency, and if it is used in staple form, water droplets will adhere to the surface of individual fibers before evaporating quickly. In knitted products, the water droplets will permeate the air spaces between the fibers and may get trapped there, which causes slowed evaporation.

- Strength: It is stronger than wool and possesses good abrasion resistance.

- Resilience: Acrylics have good resilience, which prevents creasing. Further, they have little elasticity, so they retain their shape well.

- Draping: The draping quality varies according to the type of acrylic but generally, acrylic drapes fairly well.

- Insulating: Acrylic is a good insulator because it does not conduct heat. The dog bone shape of the cross section allows overlapping; thus, air is trapped, which adds bulk and little weight. An acrylic fabric as thick and warm as wool will be approximately 20% lighter in weight than the latter fabric.

- Abrasion: Because it has high abrasion resistance, it can withstand excessive rubbing, wringing and scraping without breaking or any loss of strength.

- Lightweight: The degree of its lightness varies based upon the denier of the fiber but it is still considered to be lightweight.

- Resistance: Due to acrylic’s low absorption rate, it resists stains – the blemishes remain on the surface of the fabric and can be removed easily. Finished acrylic fabrics have good dimensional stability; consequently, they will not shrink. Household bleaches can be used safely to bleach fabrics. As acrylic dries quickly, it is less likely to be affected by mildew. Further, if mildew settles on the surface of the fabric, it can be removed easily via laundering or wiped off. Acrylic is unaffected by insects and is unaffected by perspiration. It has a good resistance to acids and fairly good resistance to alkalis. Plus, acrylic has excellent resistance to sunlight, which makes it suitable for furnishing fabrics.

- Susceptible: Orlon is thermoplastic, which means it is affected by heat. It will melt at high temperatures and become tacky at lower temperatures; thus, care must be taken when using an iron. Likewise, care must be taken when laundering acrylics because they have a tendency to pill. To reduce pilling, turn the garment inside out and use a cycle with minimal agitation and squeeze the garment rather than wringing it.

Production Flow Chart of Acrylic Fiber

Acrylic fibers such as Orlon and Acrilan are man-made fibers derived mainly from acrylonitrile. The production involves two main spinning methods — Dry-Spun Process (for Orlon) and Wet-Spun Process (for Acrilan).

Production Flow Chart of Orlon and Acrilan are given below:

Orlon: Dry-Spun Process

Acetylene/ethylene is treated with hypochlorous acid to produce a chlorohydrin.

↓

Chlorohydrin reacts with sodium hydroxide to form ethylene oxide.

↓

Hydrocyanic acid is added to the ethylene oxide, which produces cyanalcohol.

↓

Cyanalcohol is dehydrated to produce acrylonitrile.

↓

Acrylonitrile is polymerized into polyacrylonitrile resin.

↓

Polymer chips are dissolved in dimethylformamide.

↓

The polymer is then filtered.

↓

It is then passed through a spinneret.

↓

It is extruded into warm air to set the fibers.

↓

Staples are mainly created and Some continuous filament is created.

Acrilan: Wet-Spun Process

Natural gas and air are combined to make ammonia.

↓

Ammonia is combined with natural gas to produce hydrocyanic acid.

↓

Natural gas, at high temperatures, will produce acetylene, which is combined with hydrocyanic acid to produce acrylonitrile.

↓

The polymerization of acrylonitrile takes place.

↓

The powder is dissolved in a solvent.

↓

The material is then filtered.

↓

It is then passed through a spinneret.

↓

It is extruded into a coagulating bath to set the fibers.

↓

Continuous filament is created.

Finishes of Acrylic Fiber

- Anti-Static – to reduce electrostatic build-up.

- Heat Set – uses the thermoplastic property to produce a permanent shape e.g. pleats.

- Water-Repellent – for better protection from water.

Variations of Acrylic Fiber

- Spun Yarns: Staple lengths vary from 3 cm to 12 cm, depending upon the end use. They are spun on either a cotton or wool system to create fuzzy yarns. The higher the twist counts, the finer, smoother and more durable the yarns will be whereas low twist counts produce thicker and softer yarns similar to cashmere (cashmilon) that pill more easily. A number of variations of spun yarns exist that replicate variants of wool, such as worsted yarn, merino, Shetland, and lambswool.

- Vat-Dyed: Used to create permanent colours.

- Trilobal: Known as Tri-Lustra, which is an Orlon type of finish that produces a soft sheen.

- Hollow: Wintuk™ and other variations can enhance a fabric’s bounce and texture.

- Nomelle™: Is similar to Wintuk, but instead of emulating lambswool, it emulates cashmere.

- Bi-loft™: (Acrilan) is used for sportswear, primarily.

- Crimped/Looped: Type 21™: A bicomponent with permanent, latent crimp that is produced with heat and moisture. It provides greater elasticity, resilience, warmth and softness. Type 24™: a non-reversible bicomponent used for bulky hand knits and outer garment knitwear.

- High-Bulk: Thick, soft, and spongy for a luxurious hand, greater warmth and lighter weight.

- Delustre: Type 39™, 39A™: is semi-dull and used for woollen spinning; others for blending with other fibers, such as cotton. Type 88™ – Acrilan: used for awnings and banners due to its brightness and resistance to sunlight and weathering.

- Conductive: Type 90™ and Type 94™: used when anti-static and fire-resistant qualities are needed.

- Vernille: Used for chenille yarns.

- Microfiber: Acrylic is used to create a few microfibers.

Fabrics of Acrylic

A large proportion of man-made fabrics on the market today are sold under the generic name acrylic, but there are a few trade name fabrics that are either 100 percent (or some other percentage) acrylic.

Acrilan, BioFresh, Cashmilon, Courtelle, Dralon, felt, fleece, fur and jersey.

Blends

- Cotton—acrylic lightens the weight and adds bulk; the cotton contributes strength and absorbency.

- Wool—fabrics will pill less, gain good crease resistance, and becomes easier to wash. If the percentage of acrylic is higher, there is seldom a need to press the garment. High percentages of acrylic will make the fabric bulkier and stronger.

- Silk provides a cross-dyed fabric with textured effects, good handle, stability, and durability. The silk offers absorbency and strength; the acrylic makes the fabric easier to care for and shape retention.

- Viscose combinations present unusual surface and dye effects. Using a high, wet modulus viscose makes the fabric much stronger.

- Acetate provides a soft, luxurious feel with excellent draping properties, shape retention and resilience. The acrylic provides UV resistance. Unfortunately, because neither of these fibers is absorbent the garments will feel warm and clammy in humid conditions.

- Polyamide offers excellent abrasion resistance and strength to the fabric; acrylic offers bulk and a luxurious hand to the fabric making the fabric attractive. It has crease resistance and crease retention when using thermoplasticity and ease of care. As the fibers are not absorbent the fabric will be warm and clammy.

- Polyester offers greater strength and wrinkle resistance; acrylic improves abrasion resistance and handle. Care should be taken when laundering it due to the fabric’s propensity for pilling.

Uses of Acrylic Fiber

Acrylic fiber is widely used across apparel, home textiles, and industrial products due to its versatility. Used in clothing, including dresses, jumpers, scarves, gloves, socks, skiwear and sportswear as an affordable wool alternative. It can also be used for soft furnishings, such as blankets, carpets, upholstery and curtains. Further, awnings and geotextiles can be made from it. In some cases, acrylic blended with other fibers for specialized textiles.

Conclusion

Acrylic fiber finds extensive use due to its affordability, wool-like comfort, color retention, and durability, making it popular in both fashion and home textiles.