What is Fabric Whitening Treatment?

Whitening is a chemical treatment, which is applied on fibers, yarns or fabrics to make white at a desired level by bleaching and OBA treatment. Whitening is done by removing irregular natural color of fibers, yarns or fabrics.

Factors Influencing for Fabric Whitening Process:

The factors influencing whitening process are as follows :

- pH of the bath

- Temperature of the bath, and

- Time required for the process.

Process Requirements for Fabric Whitening:

Equipment Used:

Three types of Thies machines are used for whitening process. These are:

- Mini-soft

- Eco-soft

- Luft-roto

Accessories Used in Whittening:

Key accessories used in whitening process are:

- Mixing tank

- Machine Tank

- Bohme meter

- pH meter

- Eye protecting glass

- Hand gloves

- Sewing machine

- Hand lifter for carrying the batch, and

- Gum boot.

Materials / Chemicals Used:

Following materials/chemicals are used in the whitening process:

- Water

- Steam

- Compressed Air

- Wetting agent

- Detergent

- Sequestering agent

- Acid

- Anti-creasing agent

- Optical Brightener for Cotton & Polyester

- Caustic Soda,

- Hydrogen per Oxide, and

- Stabilizer, etc.

Whitening process for 100% cotton:

Steps of whitening process for 100% cotton:

The sequence for whitening process for 100% cotton fabric is as follows:

- Take water in bath at required level

- Add Detergent, Sequestering Agent, Anti-creasing Agent, Stabilizer

- Circulate the fabric for 5 minutes at 50ºC

- Add Caustic Soda and circulate for 5 minutes at 50ºC

- Add Hydrogen per Oxide and circulate for 5 minutes at 50ºC

- Add Optical Brightener agent and raise the temperature at 100ºC

- Continue circulating the fabric for 50 minutes at constant temperature (100ºC)

- Circulate the fabric and decrease the temperature at 60ºC

- Check the shade with approved shade

- Rinse and Drain

- Add Acetic acid and circulate for 10 minutes at 50ºC

- Drain

- Unload

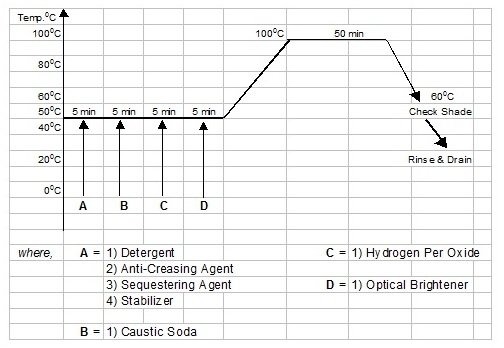

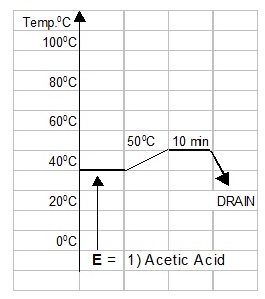

Graphical representation of whitening process of 100% cotton:

The whitening process for 100% Cotton can be graphically presented as below:

Whitening process for polyester cotton (PC) blended fabric:

Steps of whitening process for polyester cotton blended fabric:

The sequence of whitening process for polyester-cotton blended fabric is as follows:

- Take water in bath at required level

- Add Detergent, Sequestering Agent, Anti-creasing Agent, Stabilizer

- Circulate the fabric for 5 minutes at 50ºC

- Add Caustic Soda and circulate for 5 minutes at 50ºC

- Add Hydrogen per Oxide and circulate for 5 minutes at 50ºC

- Add Optical Brightening Agents and raise the temperature at 110ºC

- Continue circulating the fabric for 30 minutes at constant temperature (110ºC)

- Circulate the fabric and decrease the temperature at 60ºC

- Check the shade with approved shade

- Rinse and Drain

- Circulate the fabric for 10 minutes at 80ºC

- Drain

- Add Acetic acid and circulate for 10 minutes at 50ºC

- Drain

- Unload

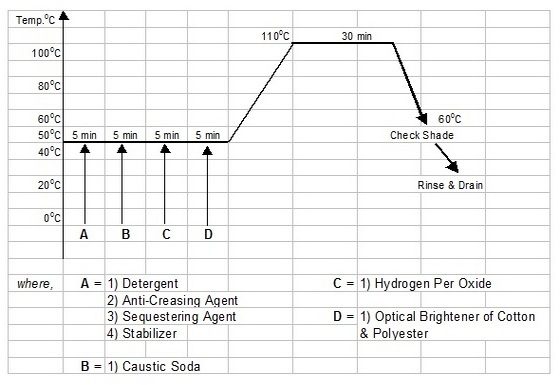

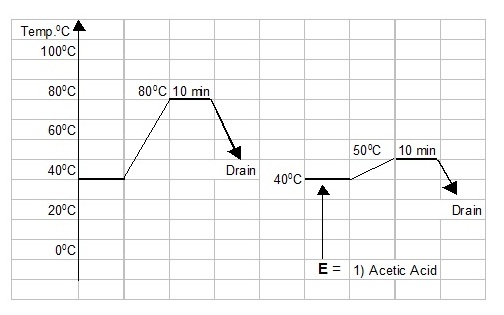

Graphical representation of whitening process for polyester cotton blended fabric:

The whitening process for polyester-cotton blended fabric can be graphically presented as below:

You may also like: Different Types of Chemicals Used in Garment Washing Plant