What is Polyester Fibre?

Polyester fibre is one of the most versatile and widely used synthetic fibres in textiles today. It is well known for its strength, durability, and versatility. The term ‘polyester’ is applied to polymers containing ester groups in their main polymeric chain, which provide the material with notable stability, durability, resistance to chemicals, and moderate resistance to heat compared to natural fibres. Polyesters are derived from a poly-condensation reaction between dicarboxylic acids (commonly terephthalic acid) and diols (commonly ethylene glycol) where water or another small molecule is eliminated, allowing long-chain macromolecules to form with consistent structural regularity.

Polyesters can be broadly classified into two types:

- Thermoplastic polyesters (e.g., PET – Polyethylene Terephthalate), which consist of fibre-forming, film-forming, and engineering application polymers that can be melted, reshaped, and processed repeatedly due to their linear molecular structure. They are widely used in textiles, packaging (plastic bottles, films), and engineering parts.

- Thermoset polyesters (unsaturated polyester resins), which are basically liquid resins that upon curing form highly cross-linked structures (solid) through reactions with cross-linkers like styrene. This produces rigid, heat-resistant networks that cannot be remelted. They are widely used as a matrix for fibre-reinforced composite materials to bind fibrous structures together because the cured resin offers excellent adhesion, dimensional stability, and mechanical strength in composite applications such as boats, automotive panels, and construction materials.

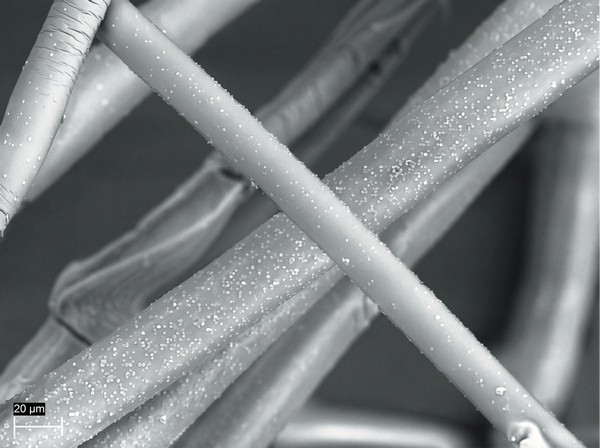

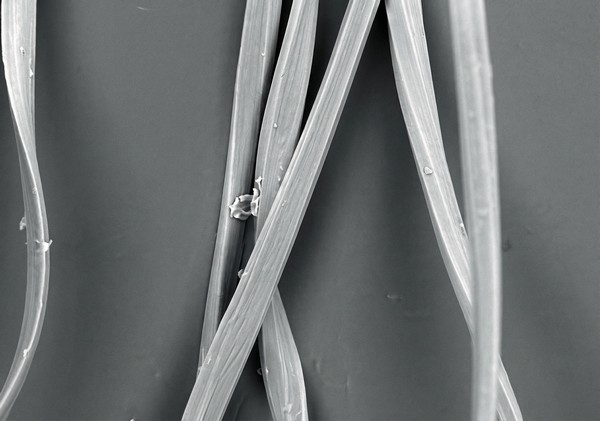

Microscopic Views of Polyester

Properties of Polyester Fibre

a) Strength: Polyester is naturally strong and stable fibre, and its strength can be pushed even further in high-tenacity industrial versions used in ropes, tyres, and seat belts.

b) Resilience: It bounces back well. The elasticity built into the fibre helps to resist creasing, which is why garments often look neat even after long wear.

c) Absorbency: Polyester is hydrophobic and one of the least absorbent fibres. It has a low moisture regain value of 0.4% compared to cotton’s ~8%, making it water repellent and quick drying. Moisture sits on the surface instead of soaking in, so it dries fast and doesn’t stain easily.

d) Draping: Draping depends on the type of polyester. Filament yarns drape satisfactorily well, trilobal versions drape even better, and spun polyester feels softer because of the air spaces between fibres.

e) Insulating: Textured, crimped, or hollow polyester traps air effectively, giving it good insulation properties, making it suitable for winter wear and bedding fillings.

f) Abrasion Resistance: It has high abrasion resistance, second only to polyamide (nylon). So, it handles rubbing and rough use extremely well.

g) Lightweight: Lightweight is dependent on denier, but overall polyester remains a lightweight fibre.

h) Resistance: Polyester doesn’t shrink because it’s heat-set during production. It also resists light degradation, making it suitable for outdoor items. The fibre stands up well against insects, mildew, acids, most chemicals, perspiration, and weak alkalis at room temperature. However, prolonged exposure to high heat (>150°C) reduces its strength and can cause melting.

i) Susceptible Points: Filament polyester’s smooth, round surface leaves fewer gaps in woven fabrics, so they trap less air and feel less warm. Although not absorbent, polyester attracts oily stains, which can be tough to remove. Careful laundering with degreasing detergents is often required. High heat can melt the fibre, so ironing must be done carefully, though its stability often means ironing isn’t needed. Spun polyester pills more easily, so gentle wash cycles are recommended.

Production Flow Chart of Polyester

Ethylene from the petroleum industry is oxidized to produce glycol monomer dihydric alcohol.

↓

Glycol monomer dihydric alcohol is combined with terephthalic acid in an autoclave at a high temperature. After that, the mixture is vacuumed.

↓

Polymerization (with the aid of a catalyst) produces a clear, colourless liquid.

↓

The molten polyester flows through a slot on a casting cylinder to form ribbons. After that it is cooled to set.

↓

The ribbons are chipped and dried to remove any excess moisture.

↓

The polymer chips are melted in a hopper.

↓

Melt Spun: the fibres are extruded and dried in cold air.

↓

Drawn: the hot fibres are drawn so that it becomes about five times its original length. This process aligns the molecules to increase the fibre’s strength. At this point, it can be textured or crimped etc to save time and money.

↓

Staple fibres are created or Continuous filament is created.

Finishes of Polyester

- Anti-Static: Polyester builds up electrostatic charge, so garments with an anti-static finish will not cling to the body and or attract dust or dirt. This is often achieved by applying conductive finishes or blending with carbon-based fibres.

- Calendering: Used to reduce pilling, apply embossed patterns and add lustre. The process involves passing fabric between heated rollers under pressure.

- Heat set: To provide permanent shapes, such as pleats as it is thermoplastic. Heat-setting locks molecular orientation, ensuring dimensional stability and wrinkle resistance.

- Shearing: For a smooth, even pile or nap. Commonly used in fleece and pile fabrics to achieve uniform surface texture.

- Water Resistant and Stain-Resistant: To improve comfort and ease of care when blended with other fibres, such as cotton. Fluorocarbon or silicone finishes are typically applied to enhance repellency.

Variations of Polyester

- Monofilament: Main industrial uses include Vituf, generic numbered polyester e.g. MX6020 and Shanton (slub). Monofilaments are single continuous strands, valued for strength and dimensional stability.

- Multifilament: Uses include Goodyear tyres, Kodel (PCDT) and Trevira. These consist of multiple fine filaments twisted together, offering flexibility and durability.

- Staple Fibres: Uses include Kodel™, Loftguard™ and Trevira. Staple fibres are short lengths spun into yarns, giving fabrics a softer hand.

- Channelled: Channels on the fibre quickly transport sweat away from the skin to the surface of the fabric e.g. Coolmax®. This enhances moisture management in sportswear.

- Hollow: A solid pin, needle or tube is supported in the centre of the circular hole. An inert gas or reactive chemical is injected into the hollow core to prevent the fibre from collapsing until it is set. It is non-allergenic and used to fill sleeping bags, duvets and skiwear. Hollow fibres trap air, improving insulation and reducing weight.

- Lobal: Trilobal, Pentalobal, Hexalobal and Octalobal – these variations provide specific effects for increased cover, opacity, wicking, comfort and softness. They can be made hollow, thus lightweight, and they often have great cushioning and insulating properties. The lobed cross-sections scatter light, giving silk-like lustre.

- High-Tenacity: Used for sewing threads, tyres, seat belts, ropes and fire hoses. Produced by controlled drawing and orientation, giving tensile strength up to 9 g/denier.

- Crimped: Taslan™ is produced in yarn production using high-pressure jets to make loops. Crimping adds bulk, elasticity, and improved insulation.

- Delustre: The materials can vary from bright to dull. Titanium dioxide is often added to reduce shine.

- Optical-Whitening: Added to the polymer in the vat before extrusion occurs to create permanent whiteness. This improves brightness and UV resistance.

- Conductive: A substance based on carbon is added to the polymer in the vat before extrusion. This reduces static build-up and is used in protective clothing.

- Microfibre: Polyester is the main fibre used in this variation; it makes fabric breathable, quick-drying, softer, lightweight and better draping qualities. Microfibres are <1 denier per filament, giving suede-like textures.

Polyester Fabrics

A large proportion of man-made fabrics on the market are sold with just the fibre content. However, there are a few fabrics that are either 100% or some percentage of polyester. Fabrics include Broderie Anglaise, Crêpe de Chine, damask, fleece, fur, lace, lawn, moiré, net, polyester/cotton, satin, shantung, taffeta, Terylene, velvet and voile. Terylene was the first commercial polyester fiber developed in the UK, widely used in apparel and furnishings.

Polyester Blends

Cotton (usually 35%) and polyester (usually 65%). The polyester provides better crease resistance, shape retention and aftercare; whereas the cotton provides absorbency and comfort. When greater absorbency and hand are needed, the blend often shifts to 50/50. Such a blend is used frequently for bedding but there is some loss of strength and resilience. Poly-cotton blends are also common in shirts and uniforms due to durability.

- Wool: The polyester provides outstanding wrinkle resistance and crease retention, abrasion resistance and durability. The wool provides good draping, elasticity and reduces the possibility of melting holes. The higher percentage of wool, the less likely the material is to pill. This blend is popular in suits and winter coats.

- Viscose: The polyester provides greater resilience, shape retention and durability. The viscose provides greater absorbency, colour and texture. Used in dresses and blouses for softness with durability.

- Acetate: There is excellent shape retention and durability. The material is clammy, however, due to its low absorption rate. The polyester adds strength to the weaker, acetate fibre. Commonly used in linings and evening wear fabrics.

- Polyamide: The polyester provides outstanding wrinkle resistance, and the polyamide adds strength and abrasion resistance. The fabric is easy to wash, quick-drying, insect-resistant and mildew-resistant making it suitable for outdoor clothing. Unfortunately, the blend is not very breathable unless microfibre variants are used. This blend is often used in activewear and swimwear.

Uses of Polyester Fibre

Clothing and sportswear, such as parkas, dry suits, nightwear, underwear, trousers, coats, jackets and dresses. It is also used for soft furnishing; carpets, rugs, curtains, sheets, pillowcases, stuffing for duvets, cushions etc. In the industrial world, it is used to make hoses, tyres, ropes, nets, sewing thread, car upholstery, sails, seat belts, tents, sleeping bags etc and uses in the medical industry such as synthetic artery replacements. Additionally, polyester films (Mylar) are used in electrical insulation, magnetic tapes, and packaging.

Conclusion

Polyester fibre has transformed the textile industry with its strength, resilience, and versatility. From everyday apparel to heavy-duty industrial uses, its production efficiency ensures it meets global demands while innovations in recycling push towards sustainability.

References

[1] Ashford, B. (2016). Fibres to fabrics. AuthorHouse.

[3] Sinclair, R. (2014). Textiles and fashion: Materials, Design and Technology. Woodhead Pub Limited.

[2] Kolanjikombil, M. (2018). The substrates: fibers, Yarn and Fabric. Woodhead Publishing.

[4] Jindal, A. J. R. (2023). Textile raw materials. Abhishek Publications.

[5] Kiron, M. I. (2022b, February 12). Polyester fiber: Properties, manufacturing and applications. Textile Learner. https://textilelearner.net/polyester-fiber-properties-manufacturing/

[6] Textile-Engineering. (2025, November 24). Properties, manufacturing and uses of polyester fibre. Textile Engineering. https://textileengineering.net/properties-manufacturing-and-uses-of-polyester-fibre/