Definition of Nonwoven Fabric:

Fabric is manufactured in three ways; weaving, knitting and nonwoven process. Among those processes nonwoven is comparatively latest process of fabric manufacturing. Nonwoven fabrics are one type of textile fabrics or a manufactured sheet made of a fibrous layer, which may be a carded web, a fiber web, or any system of randomly laid or oriented fibers or threads, possibly combined with textile or non-textile materials such as conventional woven fabrics, plastic films, foam layers, metal foils, etc., & forming them with a mechanically bound or chemically bonded textile product.

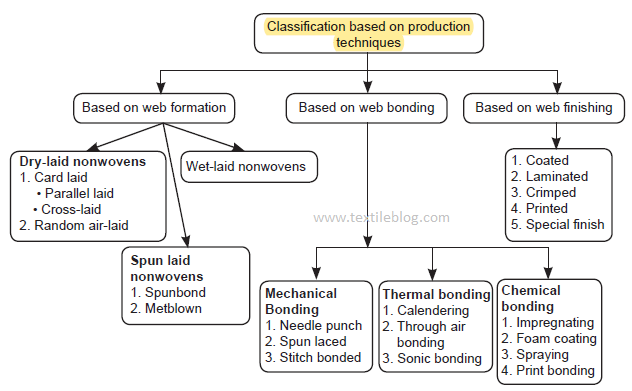

Nonwoven fabric can be classified in two ways; based on manufacturing techniques and based on structures. Classification of nonwovens based on production techniques are shown in below figures.

Nonwoven Fabric Manufacturing Techniques:

Nonwoven manufacturing techniques is basically a continuous process in which the web laying and web bonding are performed by two consecutive machines. In general, the nonwoven formation processes consists of two basic steps, web formation followed by bonding. The web formation in nonwoven production is a critical contributor of the end-use product performance. There are three basic methods of web formation: dry laid; wet laid; and polymer laid. The latter one classified as spun laid and melt blown web formations which are particularly applicable for synthetic polymers. There are three basic types of bonding: chemical, thermal, and mechanical. The natural fiber webs can be successfully bonded by mechanical process without any additives. Additional binder polymer or synthetic fiber is required for the chemical or thermal bonding.

Web Formation Process:

Dry Laid or Air Laid Nonwoven Process:

Dry laid or Air laid is the staple fiber based web laying process involves three major steps. They are fiber preparation (by opening and mixing processes), web formation (by carding or by air-lay processes) and finally web stacking (by parallellay, cross-lay, and perpendicular-lay processes). Flowchart of dry laid process is given below.

Flow Chart of Dry Laid Manufacturing Process:

Raw material

(Natural fibers, man-made fibers, inorganic fibers)

↓

Preparation

(Opening to loose material, blending)

↓

Web forming

1. Carding process (Parallel laid, cross laid)

2. Aerodynamic process (Random laid web)

↓

Web bonding

(Mechanical bonding/thermal bonding/chemical bonding)

↓

Processing

(Finishing, dyeing, printing, coating)

↓

Product

(Fiber nonwoven)

Conventional staple fibers are used are raw material in the dry-laid process, which are usually 12 to 100 mm in length. Classical textile carding or air laying machines are used to separate and orient the staple fiber mechanically for formation of fiber web. The objective of carding is to separate the fiber stock into individual fibers with minimum fiber breakage and opening and blending of different species of fibers thoroughly. In a normal carding process, the fibers are more oriented along the machine direction than the cross direction. More random web structures can be obtained by cross lapping.

In the air laying process a lap or plied card webs are fed by a feed roller. The fibers are separated by a licker-in or spiked roller and introduced into an air stream. Finally, the fibers are collected on the condenser screen to form a web after desired fiber orientation. A conveyor is used for transporting the web from condenser to the bonding area. The length of fibers used in air laying is ranging from 20 to 60 mm. A higher production speeds can be achieved with shorter fiber as they are transported easily in the air stream with larger amount of fibers per unit volume of air and deposited on the condenser. Higher air volume is required for longer fibers to avoid entanglement. The limitations associated with this air laying are speed, web uniformity and weight. It is difficult to prepare isotropic webs lighter than 30 g/m2 by the air laid process.

However, voluminous, isotropic and uniform web can be successfully prepared from a wide variety of fibers such as natural, synthetic, glass, steel, carbon, etc., by this method. This will allow the production of webs from blends of cotton with other staple fibers. The air-laid webs usually have basis weights ranging from 30 to 2500 g/m2. Typical end uses for air-laid nonwoven fabrics are the fabrics for apparel and upholstery backings, carpet backing, interlinings for garments, linings, filter media, medical fabrics, diaper coverstock, wipes, insulation, geotextiles and personal hygiene products.

Wet Laid Process:

The wet laid manufacturing process of nonwoven fabric is essentially based upon the paper making process. The wet laid process is suitable for fibers which can be dispersed in fluids. Like in the paper making process, very short fibers dispersed in water are laid on a traversing perforated lattice. Flowchart of wet laid process is given below.

Flow Chart of Wet Laid Manufacturing Process:

Raw material

(Short fibers, cellulose)

↓

Preparation

(Blending, manufacturing of fiber-water suspension)

↓

Web forming

(Spreading of suspension into a screen belt)

↓

Web bonding

(mechanical bonding/thermal bonding/chemical bonding)

↓

Processing

(Finishing, dyeing, printing, coating)

↓

Product

(Fiber nonwoven)

In wet-laid nonwoven manufacturing process the fibers are mixed with chemicals and then suspended in water to make the slurry. Then, specialized paper machines are used to drain the water off the fibers to form a uniform sheet of material like web, which is then bonded and dried.

Fibers shorter than 10 mm are suitable for wet-laid nonwoven process and the resulting fabric has a basis weight ranging from 10 to 540 g/m2. The wet laid nonwoven process has merits of high productivity, high uniformity at low basis weight and control of fiber orientation of properties, as compared to air laid process. Typical applications for wet-laid nonwovens include wipes, surgical gowns, drapes, towels, tea bags, etc.

Web Bonding Techniques:

The web bonding techniques are generally classified into three categories, mechanical, chemical, and thermal bonding, based on raw material fibers, end-use applications and web formation technology. Often, a combination of different bonding methods is used to achieve products with certain properties. Mechanical bonding can be further classified as needle punching, stitch bonding, and spunlacing (or hydroentangling). In the needle punching process, fiber web is bonded by mechanically interlocking the fibers by punching with barbed needles. As the unbonded web moves through the needle loom, the web is consolidated and becomes stronger because of the fiber interlocking. The level of consolidation is controlled by the needle punching density and depth of needle penetration.

It is the only bonding method suitable for heavyweight nonwoven fabrics. The needlepunched fabrics are extensible, bulky, conformable, distortable and extremely absorbent. Both dry laid and polymer laid webs can be needle punched. Stitch bonding is the process of bonding a web by stitching with yarns, filaments, or fibers. Spunlacing is a process of entangling individual fibers with each other using high-pressure water jets, which cause the fibers to migrate and entangle. The water jets create turbulence inside the web which causes enough interlocking between fibers to produce strong fabrics. Spunlace fabrics have more appealing properties than the needle punched fabrics. The typical applications of spunlace fabrics are wipes, medical gowns, dust cloths, garment and leather interlining etc. Faster rate of production can be achieved with spunlacing process than that of needlepunching as there is no reciprocating mechanical part. Other methods of bonding such as chemical bonding and thermal bonding are generally used for synthetic fibers.

1. Natural Fiber Needlepunched Nonwovens:

Cotton, jute and flax fibers are mostly used by various researchers and manufacturers for preparation of needlepunched nonwovens. Regular length staple cotton should be considered for needle punching since longer fibers perform better. Needles of 36–42 gauges have been found appropriate for the production of cotton needlepunched nonwovens.

Needle fineness has probably the most effect on fabric properties. Good length and length uniformity in a cotton sample is required for good quality fabrics. Bleached cotton with good lubricity is required to prevent fiber damage during needling and also needle breakage. Raw cotton fibers (unbleached) are also suitable and needles extremely well subject to proper needle selection. Needlepunched cotton nonwovens are highly efficient filter media due to the irregular fiber shape and absorption properties.

Increased tenacity in the wet condition is an important advantage with such cotton filters. To improve strength of bed blankets and industrial fabrics their scrim materials are made of needlepunched cotton.

Needlepunching is mostly used technique for manufacturing of jute nonwovens. The raw jute fibers do not produce good quality fabric because they are stiff and have no crimp. These fibers are treated with 18% (w/v) sodium hydroxide solution at 30℃ for 45 min maintaining the liquor-to-material ratio 10:1 for the development of crimp. This process is called woollensation of jute fiber. However, certain precautions are required during web manufacturing steps which are different from cotton fiber. At first, a softening treatment is necessary after jute fibers are extracted by removing root and tip portion. The softener is applied by spraying emulsion of any commercial grade hydrocarbon based mineral oil. The emulsion should contain about 1.5% oil and sprayed at 35% weight of jute fiber. After softening, the fibers are kept in a bin for conditioning. The well softened and conditioned jute fibers become suitable for web formation by carding. It has been observed that the needle punching made without the support of a reinforcing material are much bulkier in nature, and can be compressed easily under the same pressure range to a much higher extent. A better entanglement among the fibers and better reinforcing material is achieved when needle-punched fabrics are produced with reinforcing material. Appropriate technology of manufacturing jute needle punched nonwovens not only produces the diversified products from jute but also creates the value addition. Jute needle punched nonwoven products offer cost effective and market oriented diversification for jute.

Thick nonwoven fabrics also can be producing from flax fibers by needle punching method. The retted, scutched, and hackled flax fibers are suitable for needlepunching with or without any chemical treatment. Thick web of flax fiber is prepared by carding and cross lappers are used for fiber randomization. Fiber web is bonded by needlepunching for the preparation of nonwoven fabrics.

2. Natural Fibre Spunlace Nonwovens:

The nonwovens market is steadily growing with hydroentangled or spunlace nonwovens. This technology can produce nonwoven fabrics which truly have a textile quality in terms of hand, softness and comfort.

The main raw materials explored for spunlacing are viscose, cotton, polyester, polypropylene and lyocell fibers. This nonwoven technology is gaining popularity with cotton fiber due to its low wet modulus which allow it to easily respond to water jets. Additionally, the kidney shaped cross-section and twisted ribbon structure of cotton fibers are helpful for additional frictional resistance leading to better adhesion and entanglement of fibers. It is also advantageous in using unbleached cotton as it is cheaper and water jets can remove some of the oils or wax from the fiber.

Hydroentangled cotton fabrics are softer in feel, good hand, good strength, high absorbency, permeability and can be easily dyed and finished using conventional textile methods.

Years ago, processing of bast fibers such as jute, flax, hemp fiber etc. in hydro-entanglement system was unthinkable, but this also is possible today. Norafin GmbH, a Switzerland based company is involved in manufacturing of flax nonwovens and products. It is demanded that flax fiber as an environmentally responsible alternative to glass and other high-tech fibers for various technical applications and realized that spunlace process has advantages over needlepunching. Because, needlepunching is harsher mechanical process as the needles can break the fibers. Whereas, the water jets used in spunlacing process are gentler to the fiber. Also, a multilayer composite structure composed of same or different fibers blends can be prepared by spunlacing technique after configuring the manufacturing line in a state of art technology. It is a cost effective process yielding improved and uniform quality of fabric. Also, the process enables production of three dimensional fabrics, fabrics with apertures, embossed or custom patterned structures. Flaxline, a product of spunlace flax is commercially available which is described as durable, light weight, waterproof, hard-wearing, tear-resistant suitable for roofing membrane that is offered in Europe by a France-based company Soprema. The antibacterial, UV-resistant, and anti-slip property of flax fibers contribute a great virtue to its performance.

Flax/PP blend spunlace nonwoven is produces in 50/50 ratio and studied for 2D and 3D auto interior composites, acoustical and fogging properties. The blended spunlace product is prepared in an AquaJet spunlace line. It is further thermally bonded by a panel press and a stampforming press.

Major benifits of spunlace technique processing with flax fibres are significant increase of tensile strength, flexural strength and flexibility. Also, a large reduction in nonwoven thickness is possible without increase in weight of nonwoven fabric which is an added advantage.

3. Natural Fiber Stitch Bonded Nonwovens:

In this nonwoven technique fiber web is stitched like sewing. The performance of the product depends on area weight of web, stitch density and quality of sewing threads. Typically, a filament yarn is used for stitching purposes. However, cotton yarn in counts from 18 to 30 Ne (295–177 denier) are also found suitable for stitching a cotton web. Arachne and Maliwatt type of warp knitting machines are generally used for stitching to produce stitchbonded nonwovens. As with some of the other bonded webs, wet processing of stitchbonded nonwovens can be possible in fabric form like conventional textiles.

Nonwoven materials are prepared from flax straw, predecorticated flax, flax pluckings, and cut flax fibers by first needling and then stitch bonding.

4. Natural Fiber Chemical Bonded Nonwovens:

This is an easiest way of fabric formation where fiber webs are bonded using some adhesive binders that may be applied by spraying, foaming, padding or printing. A wide range of adhesive or chemical binders are available in market. Among these methods, printed patterns provide sufficient fabric bonding without imparting objectionable stiffness on it. Nonwovens wipes are manufactured using the print bonding technique.

5. Natural Fiber Thermal Bonded Nonwovens:

This process is suitable for thermoplastic fibers where fiber webs with blends of natural fibers are passed between two hot rollers (calendar rollers). The thermoplastic fiber melts or partially melts and bonds the natural fiber web. Low melt bi-component polyester or polyolefin fibers are also can be blended with natural fibers. By this method lightweight coverstock fabrics are prepared for top sheets of diapers. The exact bonding conditions are dependent on the melting temperature of the binder fibre, pressure and mass of the web. The calendar pressure need to be increased with increase in fabric mass to get efficient heat transfer and efficient bonding. The calendar temperature is kept close to the melting temperature of the binder or low melt fibre. When sheath-core bicomponent fibres are used as binder, the temperature is set above the melting temperature of the sheath, but well below that of the core polymer.

The strength of the nonwoven fabric increases with the increase in binder fiber content. Because, with more binders, there is sufficient amount of binder to melt and flow to form good bond points. Typically, 30 to 50% binder fibres are blended with cotton fibre to produce stronger thermobonded cotton nonwovens. Though a bond area of about 15% is generally used for the majority of thermoplastic fiber nonwovens, an embossed calendar roll with about 30% contact area is required to achieve good mechanical properties. Alternatively, one can use hot air-through bonding, where the web containing a proportion of thermoplastic binder is passed through a hot air oven. Inside the oven a sufficient residence time is required in the order of several seconds to minutes for achieving good bonding due to the melting and flow of the binder around the cotton fibres.

Flax nonwovens fabrics can be manufactured by thermal bonding of wet laid web blended with different contents of polypropylene (PP), polyvinyl alcohol (PVA) and bi-component polyamide 6/copolyamide (PA6/CoPA) fibers in 10–30% of blending range.

References:

- Nonwoven Fabric: Manufacturing and Applications by Rembrandt Elise

- Nonwovens: Process, Structure, Properties and Applications by T. Karthik, R. Rathinamoorthy and C. Praba Karan

- Geotextiles from Design to Applications Edited by R.M. Koerner

- Geotextile: It’s Application to Civil Engineeering – Overview by Dr. Bipin J Agrawal

- https://textilelearner.net/spunbonding-method-for-nonwoven-fabric-production/