What is Yarn Count?

Yarn count is one of the most fundamental concepts in textile engineering. Yarn count is a numerical expression that defines either the fineness or the coarseness of a yarn. In other words, it tells us how thick or thin a yarn is. The weight of the original fiber and the length of yarn produced from the raw materials indicate the thickness of the yarn which is determined by the extent of the drawing process.

The yarn count may be measured in a number of ways: the traditional fixed-length Count, Tex and Denier.

Count: 1lb of fiber is drawn out to produce a set length of yarn = Ne1

Should the one pound of yarn be drawn out further (e.g. twice as long) this will be known as Ne 2 (a finer yarn than Ne 1).

Note:

Count Ne 1 – 20 = is a coarse yarn

Ne 21 – 60 = is a medium yarns.

Ne 60 and over = is a fine yarns.

Tex: Tex is related to the weight in grams to 1 km (1000m) in length. For example, 10 Tex would weigh 10 grams per 1 km.

Manufacturers of man-made filament and spinning yarns may use Decitex (dtex) which relates to the weight of yarn in grams per 10,000m length.

Denier: It is used for man-made yarns and relates 9,000 m of yarn to the weight in grams. It is based upon the natural fiber of silk – one strand of silk measuring 9,000 m weighs 1 g. (A 10 denier yarn is much finer than a 40 denier yarn)

(However, in real terms, the fibers will not be measured in the quantity specified because doing so is wasteful. Rather, they are pro-rata weighed.)

To determine the fabric to be used for a product, the designer has to take into account the properties of the fibers, the properties of the yarn, the properties of the fabric in relation to the end use of the product. In order to ensure that yarns are fit for their end use, they should have the following properties:

- Durability: Fibers should not be shed through the production process of fabric, product construction nor in the end use of the product.

- Flexibility: During fabric construction and product manufacture the yarns will need to be flexible to withstand the continuous production processes. Flexibility also affects the performance of the fabric; this attribute can be determined by the thickness of the fiber and yarn, the yarn twist and the yarn structure.

- Resilience: Yarns must have some elasticity to withstand the rough production processes.

- Strong: They must be strong enough to withstand the harsh manufacturing processes and use within the final product.

Designers and manufacturers need to ensure that the yarns are consistent and free from faults because such imperfections adversely affect the quality of the fabric or product. For example, unwanted slubs create bumps in the fabric whereas thin areas of yarn can weaken the fabric or produce a hole in it.

The fiber content of the yarn is determined by the end use of the product which may be a single-fiber variety or a blend that consists of two or more fibers. Blending fibers is done for a variety of reasons: to improve the properties or performance of the fabric; to improve the aesthetic properties e.g. texture, color and handle; and to make the yarn cheaper to produce e.g. blending wool with acrylic.

Type of Yarn Count

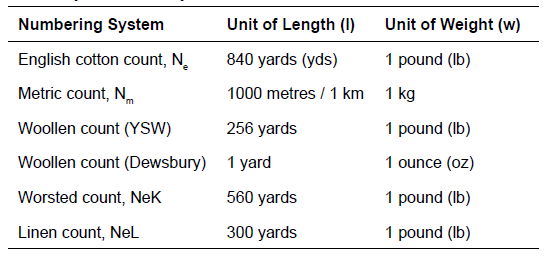

1. Yarn count by length: For cotton, flax, sisal, jute, wool and silk yarns

2. Metric yarn count (Nm): Metric yarn count (Nm) indicates the number of meters yarn weighing 1 g. Thus, Nm = length/weight = m/g

3. English yarn counts (Ne): This indicates how many units of a determined number of yards (1 yard = 0.9144 m) in 1 lb (1 lb = 453.59g); normally number of skeins at 840 yards weighing 1 lb for cotton and number of skeins at 560 yard lengths weighing 1 lb, etc. Thus, 1Ne = number of units of standard number of yards per pound.

Depending on the type of fiber, English yarn counts are subdivided as follows:

(a) Cotton (NeB) = 840 yards/1 lb = 768.1 m/453.54 g

(b) Wool (worsted) (NeK) = 560 yards/1 lb = 512.06 m/453.54 g

(c) Linen (NeL) = 300 yards/1 lb = 274.32 m/453.54 g

There is a French number (Nf) which is the number of skeins of 1000 m weighing 500 g, which is not much in use.

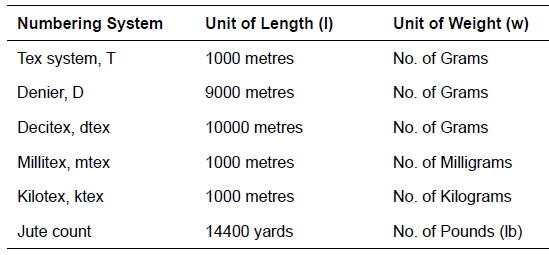

4. Yarn count by weight:

Decimal count (dtex) = g/10,000 m

Denier count (Td or den) = g/9000 m

Tex (tex) = g/1000 m

Kilotex (Ktex) = kg/1000 m

But, basically there are two types of yarn count system:

- Direct count system

- Indirect count system

a) Direct System

The weight of a fixed length of yarn is measured.

In direct system,

Heavier yarn = Coarser count, Lighter yarn = Finer count.

Examples: Tex, Denier, Pounds per spindle, etc.

b) Indirect System

The length of yarn in a fixed weight is measured.

In indirect system,

Longer length = Finer count, Shorter length = Coarser count.

Examples: English count (Ne), Metric count (Nm), Worsted count, etc.

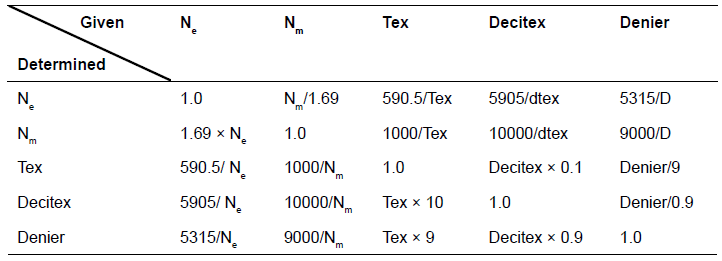

Conversion of Yarn Count

The conversion of yarn count from one system to another may be made easy with the following conversion table.

Conversion Formulas:

Nm = Ne x 1.693 = Nf x 2

Ne = Nm x 0.591 = Nf x 1.18

Nf = Nm x 0.5 = Ne x 0.947

Tx = 1000/Nm = 1 x 10-3 g/m = D/9

Nm = 1000/Tx = 9000/D

Examples of Yarn Count Conversion:

Conversion of 30 Ne to Tex and Denier (Using Table 3)

30 Ne = 590.5/30 Tex = 5315/30 Denier 30

Ne = 19.68 Tex = 177.16 Denier

Conversion of 120 Ne to Tex and Denier

120 Ne = 4.92 Tex = 44.29 Denier

Conversion of 200 Denier to Tex and Ne

200 Denier = 200/9 Tex = 5315/200

Ne 200 Denier = 22.22 Tex = 26.58 Ne

Conclusion

Yarn count is a vital textile parameter describing yarn fineness or thickness by relating weight and length measurements. Proper yarn count selection influences fabric texture, strength, and end-use suitability, making it a cornerstone in textile science and manufacturing.