What is Weave?

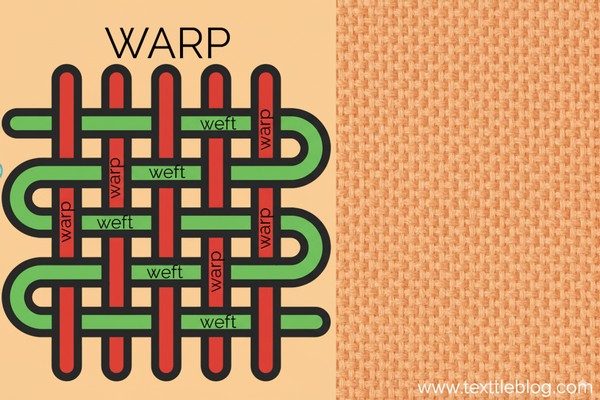

Weaving is one of the most important fabric manufacturing techniques. It involves the interlacing of two sets of yarns: warp (lengthwise) and weft (crosswise). The way these yarns interlace forms the weave. So we can say that a weave is the pattern or method of interlacing two sets of yarns (warp and weft) to form a fabric. Each type of weave gives the fabric different properties, appearances, and end uses. In this article I will discuss various common types of weaves used in fabric manufacturing.

Different Types of Weaves in Fabric

A. Plain Weave:

This is the most used method of construction. It can be used with plain, thick, thin, fancy and colored yarns. The fabric properties depend upon the thread count, fiber content and amount of fibers in the yarn. In case of plain weave, the warp and filling yarns cross alternately. Generally, the fabrics are strong, firm and relatively hard-wearing.

Variations to Plain Weave

1. Basic plain weave 1×1

The basic plain weave is 1×1, which provides a smooth surface that is ideal for applying prints as it is relatively flat. It is less absorbent and more likely to crease but will unravel less. Plain weaves can be balanced; the yarns in the warp and weft are of similar size, weight and number, or unbalanced; the yarns are either different sizes or the number of warp versus weft yarns differ in the weave count.

Examples of Fabric:

Calico: A low-cost cotton fabric that is bleached or kept its natural color. It comes in a variety of weights: light, medium and heavy. It is used by fashion designers to make a toile, used in soft furnishings for low-budget products, the base cover for sofas etc.

Voile: It is lightweight, sheer fabric made from a range of cotton, silk, viscose and polyamides. It can be plain or printed, and it is used for children’s wear, blouses, dresses and curtains.

Ripstop: High-performance fabric that features warp and weft fibers that are doubled at set intervals, often 1cm, to provide added tear resistant strength. Ripstop has high abrasion resistance, lightweight and often has a fluorocarbon finish (Teflon). It is used for kites, performance sportswear and tents.

Other balanced, plain weave fabrics include challis, cambric, chambray, cheesecloth, chintz, Crêpe de Chine, flannel, gingham, muslin, organdie, organza, percale and tweed.

2. Rib weave:

Rib is 1×1 repeated, which produces an unbalanced weave with lines (ribs) on the surface of the fabric in either the warp or weft direction, however, the ribs may or may not be seen easily. It will wear much more quickly than the basic plain weave due to the raised ribs, and it is more likely to have yarn slippage. Rib weave are two types: warp rib and weft rib.

Example of Fabric:

Poplin is a warp-faced cotton fabric that has weft ribs on the surface. The warp is fine, and the weft is coarser and can be plain or printed. It is used for shirts, summer jackets, raincoats and children’s wear. Finishes can be added, such as water-resistance, waterproofing and fire-resistance.

Other ribbed fabrics include Bedford cord, broadcloth, Crêpe de Chine, grosgrain, rep, shantung and taffeta.

3. Basket, matt or hopsack weave:

In matt, basket or hopsack weaves two or more ends and two or more picks weave as one. Basket Weave is 2×2, 3×2, and 4×4 being produced using the traditional basket-making technique. It is a much more loosely woven fabric, and is prone to snagging and fraying. It is more flexible, but it is likely to stretch, have yarn slippage and shrink in the wash.

Example of fabrics includes canvas, duck, hopsack, monk’s cloth and sailcloth.

4. Slack weave:

Slack weave produces a distinctive crinkle effect on the fabric via one of the following methods:

- Stripes under different degrees of tension cause the looser tension wefts to crinkle, as seen in tablecloths and dresses.

- Linen and cotton fabrics are treated in caustic soda results in expansion of the fibers, which cause them to crinkle because they cannot expand the fabric.

- Using yarns with different shrinkage rates can be woven so when the fabric is in a wet finishing process the yarns will shrink at different rates causing the fabric to crinkle.

An example of a slack weave fabric is seersucker.

5. Swivel weave:

This variation to plain weave incorporates a design into the weave by using small shuttles that insert extra weft around a few warp yarns while the main weft creates the fabric. This process produces dot motifs, small fringes or isolated motifs. The yarn of the shuttle runs behind the fabric, and the ends are cut at the beginning and end of each motif. The ends are held in place by subsequent full-length weft yarns, which results in a less durable motif, especially if the fabric is stretched or washed. This technique is often used on sheer fabrics such as Swiss Dot, which is made from cotton batiste.

6. Lappet:

This variation is similar to swivel weave: it creates small motifs during the fabric construction, but they are made from needles that stitch the design. Again, the yarns run behind the fabric, but the fabric is more durable than the swivel weave fabrics because the ends are tied off.

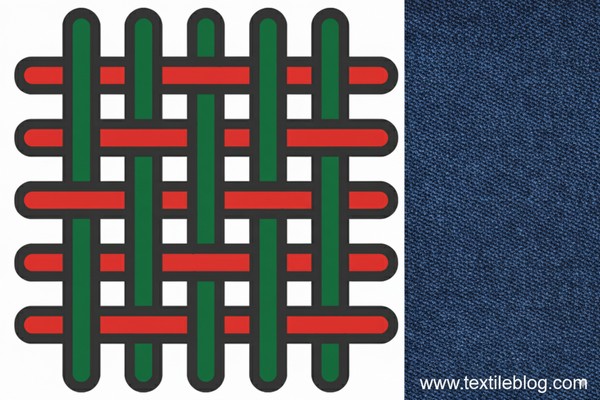

B. Twill Weave:

Twill weave produces a fabric with distinctive diagonal lines that can run bottom left to top right (known as a Z or right-hand twill) or bottom right to top left (known as an S or left-hand twill). These diagonal lines are created by either the warp or weft faced yarns, and the angle varies between fifteen degrees and seventy-five degrees, however, a forty-five degree angle is considered to be normal twill. Above that normal angle, it is called steep twill; below that normal angle it is called reclining twill. The height of the ridge varies according to the amount of yarn fed into the loom by the height of the back rest above the warp beam: a low back rest provides a soft ridge and a high back rest provides a high ridge. Also, the combination of the direction of the twill and the twist of the yarn affect the height of the ridge:

➢ Right-hand twill – Z twist yarn will provide a low warp ridge;

S twist yarn will provide a high warp ridge.

➢ Left-hand twill – Z twist yarn will provide a high warp ridge;

S twist yarn will provide a low warp ridge.

The twill weave is the strongest, closely woven, heavier and most hard-wearing of the weave structures because the yarns are more compacted. They can be produced in fancy designs.

Examples of Fabric:

Denim: Denim is warp-faced and made from cotton using colored (usually blue) warp and white weft; often 2×1 or 3×1. Usually left hand twill using a Z twist yarn to produce a high ridge. It is strong, durable and light to heavy in weight. It is used mainly for work clothing (traditionally), fashionable trousers and jeans, jackets and skirts.

Gabardine: 2×2 warp-faced twill of combed cotton, viscose or worsted yarns. It is used for coats, trousers and other garments.

Diamond weave: Diamond weaves are achieved by combining two symmetrical zigzag weaves of equal repeat. Diamond designs are vertically and horizontally symmetrical.

Drill: It is warp-faced, strong, durable and medium to heavy in weight using 2×1 or 3×1 construction. This is often called khaki, which is used for military clothing and ticking, which is used for pillows to prevent feathers from poking out.

Diaper weave: Diaper weaves are produced when we combine two

Viyella: 2×2 weave using a blend of wool (55%) and cotton (45%) in both warp and weft. The fabric has a nap (brushed surface), and it is used for shirts, dresses and children’s wear.

Other fabrics:

Even-sided twill: Flannel, herringbone twill, houndstooth, plaid and serge.

Warp-Faced: Chino.

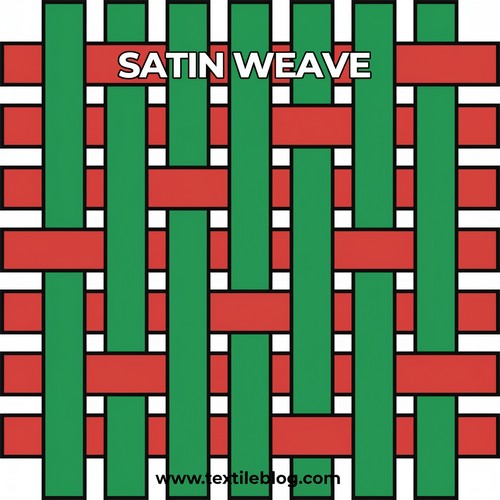

C. Satin Weave:

Satin weave is a fabric with a high weave count and is warp-faced with smooth yarn floats across the face of the fabric, whilst the weft, which has a tight twist, moves across the back. The warp or float yarns are smooth filament fibers to allow for superb light reflection, which creates a very shiny surface. These fabrics drape well in soft folds, but sometimes the floats on the surface can snag and can cause problems while manufacturing products, especially if a slightly blunt needle is used. It is used for coat linings, jackets, curtain linings, evening wear and ribbons.

D. Sateen Weave:

This is a similar to satin but it is the smooth, weft yarns which float across the face of the fabric, so warps show on the back only. It is often used for the base of more complex fabrics, such as crêpe and curtain linings.

Examples of Fabrics:

Damask: Made from mercerized cotton of one color. It’s a combination of satin and sateen weaves, the surface of the fabric changes between warp and weft faced, that creates a pattern on the surface of the fabric. However, due to the complexity of changing from satin to sateen, to incorporate the pattern during the fabric construction, a jacquard loom is often used. Uses include curtains, upholstery fabrics and tablecloths.

Duchesse Satin: A high weave-count, heavyweight satin fabric used for evening and wedding gowns. A sharp machine needle should be used on this fabric because, otherwise, snag lines may be visible on the end product.

Other Fabric: Satin back crêpe is a very slinky, high-lustre reversible fabric. Antique satin or Dupion uses slub yarns in the weft, which gives it a textured appearance suitable for garment linings, the smooth surface allows the garment to slide on and off easily.

Curtains and curtain linings often feature sateen weave and slipper satin is used often for ballet shoes.

E. Crêpe Weave:

These fabrics have a pebbly, crinkled, or puckered appearance, which can be created in a number of ways:

- Using a yarn with a high S—and Z-twist count (or using crinkled yarns) with a plain weave. When the fabric relaxes, the yarns twist back on themselves to create the crinkled effect. Alternating the use of S—and Z-twist yarns accentuates the pebble effect. This effect would be difficult to achieve on a jet loom because the yarns will relax and twist before the beater bar can hold it in place; therefore, the weft becomes too short for the width of the fabric.

- Using a crêpe weave that is a combination of plain and satin weaves with varying length floats in either the warp or the weft. Using ordinary yarns there will be limited strength, durability and poor draping quality.

- Using a chemical or thermal treatment to force the fabric to shrink differently, again, using a plain weave.

If a combination of yarns and weaves are incorporated, the fabric will have good texture, resilience and will drape well.

Examples of Fabrics:

Crêpe-weave fabrics using spun or filament yarns are momie or granite and are based on satin weave, which is an even-sided fabric. It lacks long floats because the tight-twist yarns of wool or blends provide a distinctive bobble to the surface where the self-twisted yarns are raised to the surface. Sand crêpe is a medium—to heavy-weight cloth that has a sandy texture. Moss crêpe combines crêpe weave with high twist, plied yarns that may be alternated with regular yarn to provide a textured surface.

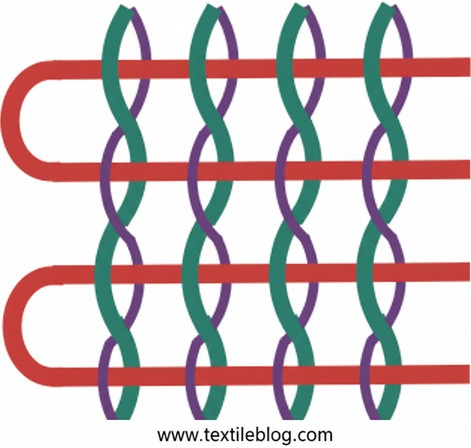

F. Leno Weave:

The leno weave is also known as the gauze or doup weave. The warp yarns are set up in pairs so that they can twist around each other via the use of a doup attachment, which is a hairpin-like device attached to the heddle. The attachment pulls one of the warp yarns in the pair up or down, to the left or to the right, to make it twist between each weft insertion so securing a firm hold on the filling yarn, which prevents it from slipping out of position. This process produces a sheer fabric with an open-weave effect that has a low yarn count but is durable and strong. This fabric is suitable for curtains as it has excellent draping qualities and no yarn slippage, but it allows light and air to pass through it. The fabric names are grenadine and marquisette.

G. Pile Weave:

This fabric usually involves three yarns: two ground yarns, being the warp and weft yarns, plus the pile yarn, which can be either warp or weft. The pile yarn has either loops (uncut pile) or tufts (cut pile) that stand up from the surface of the weave and can be either twill or plain weave.

1. Cut pile:

There are three methods to producing a cut pile:

a) Filling Yarns:

These are weft yarns that float over one or two ground yarns to form loops that are cut. The yarns that float pass over a number of ground yarns, depending upon how long the pile is and whether it is to be a ribbed fabric.

After a pick, a machine raises the floats and cuts them with rotating knives, so lifting the pile. Corduroy and needle cord, usually made from cotton, are produced this way – a woven, weft, cut-pile fabric, which has ribs running down the length of the fabric. The number of ribs can vary between one and twenty-two per 2.5 cm. Needlecord has fine, small ribs, whereas corduroy has fatter, wider ribs. The rib pile produced for these fabrics are from the filling yarns that are held in place by a single or double warp yarn, the latter provides more stability. The pile is made from two weft insertions in V, W, or a combination of V and W shapes.

V Pile: the insertions of the two wefts into the warps show the float to the next insertion. These floats are then cut to produce the rib. This is the easiest method to cut, but the pile has a tendency to come out of the fabric.

W Pile: The insertions into the warp in the W formation provide more stability when the floats have been cut because they are less likely to be pulled out of the fabric during use or aftercare.

Combination of V and W: This is usually used in wide-whale ribs because the outer W pile offers stability to the outer edge of the rib and the V offers good height. There is also good stability in the pile during use and during aftercare.

The cutting of the last two methods is more difficult because the center of the W or the ground fabric (warps) must not be cut to ensure that the pile is held securely. This is a time-consuming process because the floats are raised by a grooved guide needle, and the floats are cut by a rotary blade passing along the groove of the needle.

Velveteen is made from the weft yarns (which differentiates it from velvet which uses the warp yarns), by using the V, W or V and W piles continuously, without floats, with a height under 3 mm. However, there is a very high pick count per 2.5cm, over four hundred, which makes it a very costly production process.

b) Wire method:

The loom has wires with razor-sharp edges. Extra warp yarns are placed over the wires while a predetermined set of wefts are woven. When the wires are removed, they cut the warp yarns at the same time to produce the pile. This produces a close, dense pile for velvet, plush, panne and crushed velvet. Velvet –this has a cut warp pile which provides a dense, soft, lustrous and rich fabric that has a nap; is smooth in one direction and is rough in the other direction, which gives the fabric a darker or lighter shade depending which way up it is held. When using this fabric, the smooth surface should run up the garment to instil the darker shade. Cotton velvet is used for jackets and upholstery; wool velvet is used for suiting; silk velvet is used for luxury products; and polyester is used for clothing and upholstery.

c) Double-Cloth:

Two fabrics are woven at the same time. An extra set of yarns are woven to hold the two layers together. These extra yarns are cut between the two layers by a knife travelling across the loom, which produces the pile.

The patterns created by the yarns travelling between the two layers are V, W, or a combination of both shapes, similar to the aforementioned shapes, but continuous without the floats.

The W and V/W combination are the more durable cut piles because they are held in place more securely. The height of the pile is determined by the distance between the two layers, but usually, velvet has a height of 3 mm; above 3 mm the fabric is known as plush.

2. Loop or Uncut pile:

Loop piles can be produced in two ways:

- Wires without cutting edges – the weaving is the same as it is for the cut-pile wire method, but as the wires are withdrawn, the loops remain.

- Slack tension or terry – this has an extra set of warp yarns woven into the fabric from a warp-pile beam. Two wefts are placed over all warp yarns (those from the warp beam and those from the warp-pile beam). The warp beam yarns are held under tension while those from the warp-pile beam are slackened. A third weft is placed in, and the reed or beater bar comes down to hold all three wefts together, which pushes up the slackened warp yarns forming loops. The pile can be produced on either side of the fabric.

Fabrics: Terry towelling with loops on both sides is used for towels, dressing gowns, bathmats, etc. Terry velour has a loop pile on one side and a cut on the other and has similar uses as terry towelling. Some carpets and rugs use loop pile construction process.

Conclusion

Weaves play a vital role in defining the look, feel, and function of fabrics. Different types of weaves give fabrics their unique beauty and purpose. While plain, twill, and satin are the three basic weaves, variations like basket, leno, jacquard, and pile expand the possibilities of textile design.

References

[1] Ashford, B. (2016). Fibers to Fabrics.

[2] Purushothama, B. (2016). Handbook on fabric Manufacturing: Grey Fabrics: Preparation, Weaving to Marketing. Woodhead Publishing India in T.

[3] Textile and Clothing Design Technology. (2017). In CRC Press eBooks. https://doi.org/10.1201/9781315156163

[4] Shenton, J. (2014b). Woven Textile Design. Laurence King Publishing.

[5] Hayavadana, J. (2016). Woven fabric structure design and product planning. CRC Press.