Fabric Finishes

Fabric finishes are processes applied to textiles after weaving or knitting, to improve their appearance, feel, or performance. These finishes can be either functional (like making fabric water-resistant) or aesthetic (like giving it shine or softness).

Once the fabrics have been constructed, they may be finished in a variety of ways before they are sent to product manufacturers.

Fabrics are finished for a number of reasons; to add certain performance properties (e.g. prevent shrinkage), enhance the surface of the fabric or aesthetics (e.g. raise the nap) or encourage people to buy a product (e.g. starching).

The performance and aesthetic finishes can be carried out by physical/mechanical or chemical/resinous means. The life expectancy of these finishes are in are four categories:

- Permanent – usually chemical and will not change throughout the life of the fabric.

- Durable – may last the lifetime of the product, but its effectiveness diminishes.

- Semi-durable – lasts through several washes or dry-cleaning processes, but it will eventually disappear though it is renewable.

- Temporary – very short-term; often used on end products to encourage people to buy them e.g. the starch on hankies, which is removed after the first few washes.

The finishes will, to some degree, affect the characteristics of the fabric.

Let’s explain some of the most common types of fabric finishes used in the textile industry.

Different Types of Fabric Finishes

Generally we can classify fabric finishes in the following three ways:

- Basic Finishes: Cleaning and tentering.

- Aesthetic Finishes: Shearing, brushing, mercerizing, calendering and puckering.

- Performance Finishes: Antimicrobial, anti-static, crease-resistant, easy-care, flame-resistant/retardant, hydrophilic, permanent pleat, plasma, mothproof, shrink-resistant, photo-protective, antioxidant, stain-resistant, stiffening, Trubenized, stonewashed, bio-stoned and bio-polished.

Briefly explain of these above finishing process of fabric.

1. Basic Finishes of Fabric:

One of the first steps in fabric finishing is cleaning, which involves removing all the dirt, natural oils, waxes, and leftover chemicals from the fabric after it has been woven or knitted. This process helps prepare the fabric for further treatments like dyeing or printing. Cleaning usually includes steps like desizing, scouring, and bleaching to make the fabric clean, white, and absorbent. After cleaning, the fabric often becomes wrinkled and may shrink, so it goes through a process called tentering (also known as stentering). In tentering, the fabric is clipped on both sides and passed through a heated frame to stretch it to the correct width and straighten it. This helps remove wrinkles and ensures the fabric has a smooth, even appearance and the right dimensions. Together, cleaning and tentering make the fabric ready for the next stages of finishing.

2. Performance Finishes:

Performance finishes may cause fabrics to retain their shape better, repel or attract water, crease less, shrink less, etc. The type of finish applied to fibres and fabrics will be determined by the properties specified by the end product in relation to the fabric used.

Major performance finishes are briefly explain below:

- Antimicrobial Finish: Stops bacteria and fungi from growing on fabric, keeping it fresh and odor-free. Used in sportswear and hospital textiles.

- Anti-static Finish: Prevents static electricity buildup in clothes, so they don’t stick to your body or attract dust.

- Crease-resistant Finish: Helps fabric resist wrinkling, so clothes look smooth even after wearing or washing.

- Easy-care Finish: Makes fabric simple to wash, dry, and wear with less ironing and maintenance.

- Flame-resistant/Retardant Finish: Protects fabric from catching fire easily or slows down burning. Used in uniforms, curtains, and kids’ clothes.

- Hydrophilic Finish: Makes fabric absorb water better. It helps in sweat-wicking and keeps you dry.

- Permanent Pleat Finish: Keeps pleats or folds in place permanently, even after washing.

- Plasma Finish: Uses gas (not liquid) to treat fabric at a microscopic level. Improves surface properties like softness, dye uptake, or water repellency without chemicals.

- Mothproof Finish: Protects wool and other natural fabrics from moth damage.

- Shrink-resistant Finish: Stops fabric from shrinking after washing or drying.

- Photo-protective Finish: Blocks harmful UV rays from the sun. It protects both the fabric and your skin.

- Antioxidant Finish: Protects fabric (and sometimes skin) from aging and environmental damage by blocking harmful free radicals.

- Stain-resistant Finish: Makes fabric resist absorbing stains from food, drinks, or dirt. Spills can be wiped off easily.

- Stiffening Finish: Gives fabric a firm or stiff feel. Used for collars, curtains, or craft fabrics.

- Trubenized Finish: A special process that gives synthetic suits (like polyester) a wool-like look and feel, with better drape and shape retention.

- Stonewashed Finish: Fabric is washed with stones to give a soft feel and faded, worn-out look. Common in jeans.

- Bio-stoned Finish: Instead of real stones, special enzymes are used to create a stonewashed look, which is more eco-friendly.

- Bio-polished Finish: Enzymes are used to clean the surface of cotton fabric, making it smoother, shinier, and less prone to pilling (fuzz balls).

3. Aesthetic Finishes:

Aesthetic finishes affect the appearance of the fabric and include such properties as the drapability, lustre, surface appearance or texture. For example some may become rigid whilst others become softer. Some fabrics maybe shiny and smooth whilst others may become textured and dull. These finishes make fabric look better, feel better, or both—helping designers create attractive and stylish textiles.

Here are briefly description of fabric aesthetic finishes:

- Shearing: Cuts off the loose or uneven surface fibers from the fabric to make it smooth and even. It gives a clean and neat look.

- Brushing: A roller with tiny wires gently brushes the fabric surface to raise soft fibers, making it feel warm and fuzzy—often used in flannels or winter wear.

- Mercerizing: Cotton fabric is treated with a special chemical (caustic soda) to make it stronger, shinier, and better at absorbing dyes. It also improves smoothness.

- Calendering: The fabric is passed through heated rollers to make it flat, smooth, and sometimes shiny. It looks more polished after this finish.

- Puckering: Creates small, intentional wrinkles or ripples on the fabric surface to give it a textured, decorative look—used for fashion or design purposes.

Fabric Finishing Techniques

Fabric finishes are done in the following ways.

A. Mechanical or Physical Process:

To change the fabric’s character this process involves the use of machinery either by friction e.g. brushing the surface of the fabric to create a nap; heat e.g. calendering to change the surface of the fabric; pressure e.g. causing shrinkage for crêpe; and tension e.g. tentering to reshape fabric.

B. Chemical or Resinous Process:

This process involves the use of resins or chemicals to create the following finishes: mercerized, fire-resistant, waterproof, stain resistance, anti-static, easy-care and mothproof. The finishes may change the feel or handle of the fabric.

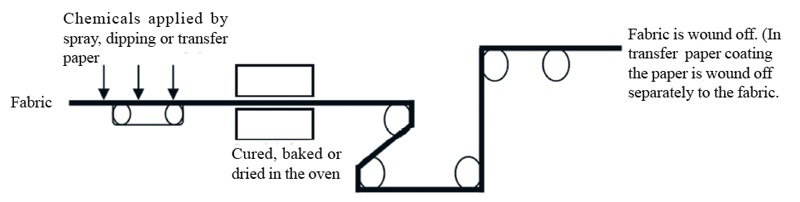

Some finishes are applied as a coating to provide weather protection, reflective properties, sheens and holographs. These finishes include wax and synthetic resins that are applied to the surface of the fabric or applied via transfer paper and fixed onto the fabric by putting it in a curing oven.

C. Traditional Fabric Finish:

In ancient times, people in Asia and the Far East used conch shells to give fabric a shiny and smooth surface. Instead of modern machines, they rubbed the shells by hand over the fabric or attached them to a swinging tool (like a pendulum) that moved back and forth. The fabric was placed on a grooved wooden bar, and this rubbing process helped create a natural lustre (shine) on the surface. This was an early form of calendering, done without electricity—just skill, effort, and natural tools.

Conclusion

Fabric finishes play a huge role in the performance, durability, and aesthetics of textiles. Whether it’s making clothes more comfortable, adding protection, or simply making them look better, these finishes are an essential part of modern textile manufacturing. Understanding fabric finishes can help you choose the right clothes, home textiles, and outdoor gear for comfort, function, and style.